Maintenance (Continued)

2. Remove Coupling (Ref. No. 3) and

Rod (Ref. No. 2) by unthreading

Screws (Ref. No. 4).

3. Loosen, but do not remove set

screws in Shaft Seal Assembly

(Ref. No. 7).

4. Unscrew Shaft Seal Assembly in a

counter-clockwise direction, then

carefully lift off of Shaft (Ref.

No. 21).

REASSEMBLY

IMPORTANT: Pump Shaft may have

been gouged from set screws. Before

installing new Shaft Seal Assembly,

smooth-over these gouges with a light

grit emery cloth to prevent damage to

new seal.

1. Once shaft is free of burrs, lubricate

Shaft and o-ring cavity in Adapter

(Ref. No. 8) with soapy water.

2. Carefully slide new Shaft Seal

Assembly onto Shaft, then tighten in

clockwise direction and torque to

26 ft-lbs [35 N-m].

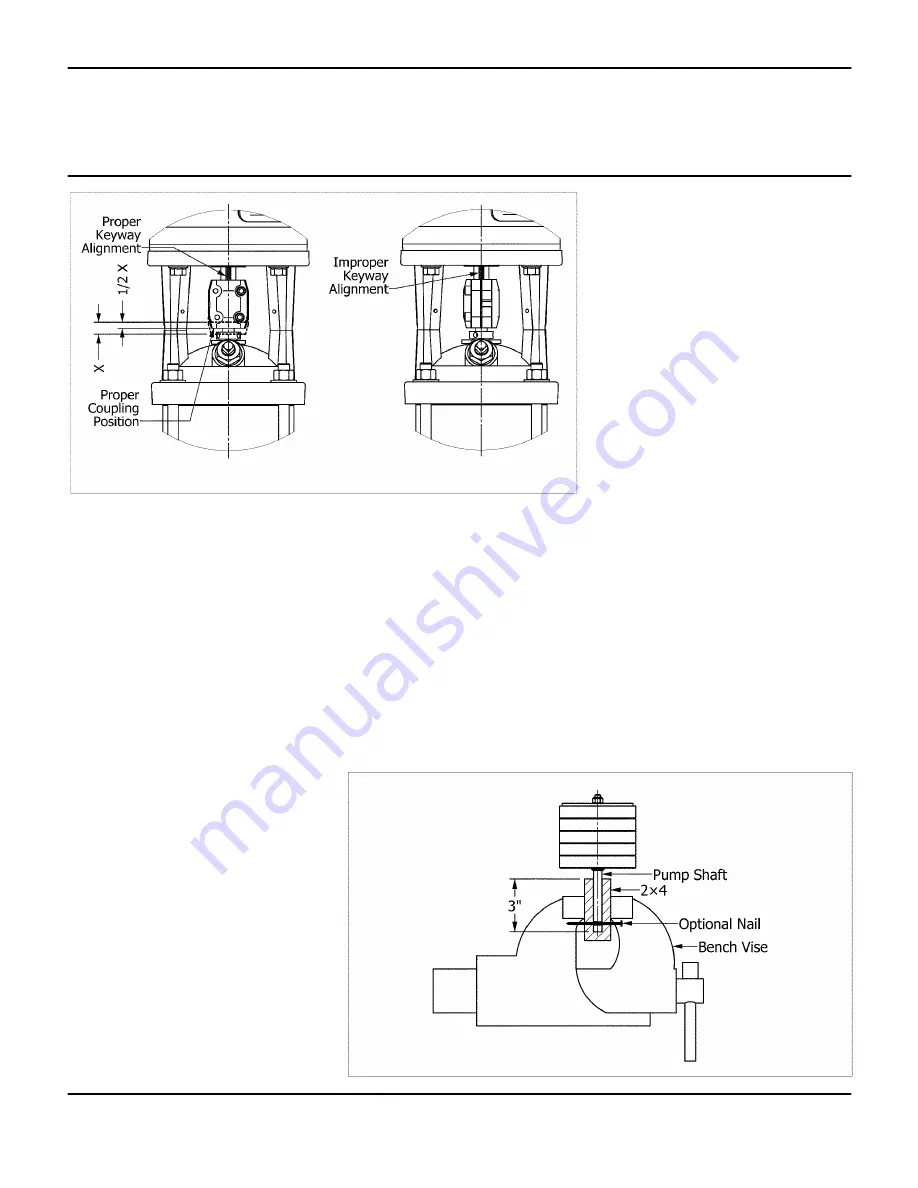

3. Mark or otherwise note shaft height.

Lift shaft as high as it will go, then

lower it back down ½ the total

distance. Maintain this position

while evenly tightening 3 set screws

in seal collar and torque each to

2 ft-lbs. [2.5 N-m].

4. Place Rod thru Shaft, then reinstall

Coupling and screws but do NOT

tighten.

5. Proceed to Reassembly under Motor

Replacement section.

PUMP OVERHAUL/INSPECTION

To inspect condition of pump internals,

proceed as follows:

NOTE: To facilitate overhaul, a handy

holding device can be made easily. Take

a short piece of 2×4 lumber and on the

narrow side, drill a 1/2” diameter blind

hole 3” deep. Place block into bench vice

with hole facing up to receive pump

shaft after step 5 (see Figure 5).

DISASSEMBLY

1. Proceed to Disassembly under Shaft

Seal Replacement.

2. Remove 4 Fastener sets (Ref. Nos.

15 & 16).

3. Lift Adapter (Ref. No. 8) from pump,

use a soft mallet to break loose if

necessary.

NOTE: Inspect o-ring groove in Adapter

after o-ring is removed. Rust/pitting in

this region may cause leaks, be sure to

clean or replace Adapter entirely if

damage is excessive.

4. Remove wave Spring (Ref. No. 18)

from Adapter.

NOTE: Inspect wave Spring for cracks

and replace if found.

5. Pump internals can now be removed

all at once. Use pump Shaft (Ref.

No. 21) as a handle and gently lift

the entire assembly out. If stage-1

Volute (Ref. No. 38) stays behind, it

can be removed and inspected later.

Specifications Information and Repair Parts

Manual

PM1, PM3, and PM5 Series

Multistage Centrifugal Pumps

Vertical Inline Models

4

Figure 4 – Coupling Alignment

Figure 5 – Inspection