5

IO-230F

08/04

maximum heat and allow the system to reach steady state

conditions. Insert two thermometers, one in the return air

and one in the supply air. The temperature rise is the supply

air temperature minus the room air temperature.

Use HKR specification sheets to determine the HKR

available for a given air handler.

HKR INSTALLATION

Follow instructions listed in Installation and Operating

Instructions shipped with the heat kit.

LOCATION

WARNING

THIS AIR HANDLER IS DESIGNED FOR INDOOR

INSTALLATION ONLY. DO NOT INSTALL OUTDOORS.

When installing this air handler consideration to minimize

the length of refrigerant tubing is to be given. Do not install

the air handler in a location either above or below the

condenser that violates the instructions provided with the

condenser. The clearance from a combustible surface to

the unit is 0". However, service clearance is to take

precedence. Allow a minimum of 24" in front of the unit for

service clearance. When installing in an area directly over

a finished ceiling (such as an attic), an emergency drain

pan is required directly under the unit. See local and state

codes for additional requirements. When installing this unit

in an area that may become wet, elevate the unit with a

sturdy, non-porous material. In installations that may lead

to physical damage (i.e. a garage) it is advised to install a

protective barrier to prevent such damage.

DUCTWORK

This air handler is designed for a complete supply and

return ductwork system.

CAUTION

DO NOT OPERATE THIS PRODUCT WITHOUT ALL

DUCTWORK ATTACHED.

To ensure correct system performance, the ductwork is to

be sized to accommodate 375-425 CFM per ton of cooling

with the static pressure not to exceed .5" WC. Inadequate

ductwork that restricts airflow can result in improper

performance and compressor or heater failure. Ductwork

is to be constructed in a manner that limits restrictions and

maintains suitable air velocity. Ductwork is to be sealed to

the unit in a manner that will prevent leakage.

Return Ductwork.

DO NOT TERMINATE THE RETURN

DUCTWORK IN AN AREA THAT CAN INTRODUCE

TOXIC, OR OBJECTIONABLE FUMES/ODORS INTO

THE DUCTWORK. The return ductwork is to be introduced

into the air handler bottom (upflow configuration).

Return Air Filters

.

Each installation must include a return

air filter. This filtering may be performed at the air handler

or externally such as a return air filter grille. Air handlers

mounted in the downflow orientation, including “B” series,

require external filtering. A washable filter is available as

an accessory. To ensure optimum performance frequent

f

i

l

t

er cl

eani

ng i

s advi

sed. Refer to

Table 5

for the appropriate

filter.

ARUFor

ARPT

model

ARPF

model

AEPT

model

Filter

Number

Qty

Required

018-032

024, 036

n/a

FIL 18-32

1

036-042

n/a

30

FIL 36-42

1

048-061

048, 060

036, 060

FIL 48-61

1

Table 5

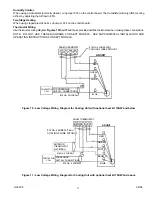

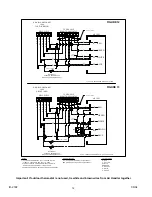

ELECTRICAL SUPPLY WIRE AND MOP

WARNING

TO AVOID THE RISK OF FIRE OR EQUIPMENT DAMAGE,

USE ONLY COPPER CONDUCTORS. BEFORE

SERVICING OR INSTALLING THIS EQUIPMENT, THE

ELECTRICAL POWER TO THIS UNIT

MUST

BE IN THE

“OFF” POSITION AND ALL POWER SUPPLIES

DISCONNECTED.

CAUTION

MORE THAN ONE DISCONNECT MAY EXIST. FAILURE

TO OBSERVE THIS WARNING MAY RESULT IN AN

ELECTRICAL SHOCK THAT CAN CAUSE PERSONAL

INJURY OR DEATH.

WARNING

THE UNIT

MUST

HAVE AN UNINTERRUPTED,

UNBROKEN ELECTRICAL GROUND TO MINIMIZE THE

POSSIBILITY OF PERSONAL INJURY IF AN ELECTRICAL

FAULT SHOULD OCCUR. THE ELECTRICAL GROUND

CIRCUIT MAY CONSIST OF AN APPROPRIATELY SIZED

ELECTRICAL WIRE CONNECTING THE GROUND LUG

IN THE UNIT AND CONTROL BOX WIRE TO THE

BUILDING’S ELECTRICAL SERVICE PANEL. OTHER

METHODS OF GROUNDING ARE PERMITTED IF

PERFORMED IN ACCORDANCE WITH THE “NATIONAL

ELECTRIC CODE” (NEC)/”AMERICAN NATIONAL

STANDARDS INSTITUTE” (ANSI)/”NATIONAL FIRE

PROTECTION ASSOCIATION” (NFPA) 70 AND LOCAL/

STATE CODES. IN CANADA, ELECTRICAL GROUNDING

IS TO BE IN ACCORDANCE WITH THE CANADIAN

ELECTRIC CODE CSA C22.1. FAILURE TO OBSERVE

THIS WARNING CAN RESULT IN ELECTRICAL SHOCK

THAT CAN CAUSE PERSONAL INJURY OR DEATH.

Inspection of the Building Electrical Service

This unit is designed for single-phase electrical supply. DO

NOT OPERATE ON A THREE-PHASE POWER SUPPLY.

Measure the power supply to the unit. The supply voltage

must

be in agreement with the unit nameplate power

requirements and within the range shown in

Table 6

.

Nominal Input

Minimum Voltage

Maximum Voltage

208/230

187

253

Table 6