27

Furnace

Control

Remote Condensing Unit

Heating/Cooling

Room Thermostat

Y

Y1

Y1

Y2

Lo

-H

e

a

t

Hi

-H

e

a

t

Co

o

l

Li

n

e

-H

T4

T2

T3

T5

ECO-TECH

MOTOR

Field

Supplied

Relay

Y2

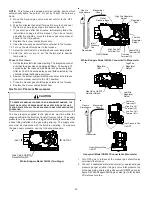

Field Wiring for GME95 /AMEH96 Furnacewith 2-Stage

Condenser

115 V

OLT

L

INE

C

ONNECTION

OF

A

CCESSORIES

(E

LECTRONIC

A

IR

C

LEANER

)

HIGH VOLTAGE!

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRICAL

SHOCK

,

DISCONNECT

ELECTRICAL

POWER

BEFORE

SERVICING

OR

CHANGING

ANY

ELECTRICAL

WIRING

.

WARNING

The furnace’s integrated control module is equipped with line voltage

accessory terminals for controlling power to an optional field-supplied

electronic air cleaner.

The accessory load specifications are as follows:

Electronic Air Cleaner

1.0 Amp maximum at 120 VAC

Turn OFF power to the furnace before installing any accessories.

Follow the air cleaner manufacturers’ instructions for locating, mount-

ing, grounding, and controlling these accessories. Accessory wiring

connections are to be made through the 1/4" quick connect terminals

provided on the furnace integrated control module. The electronic air

cleaner hot terminal is identified as EAC-H. The electronic air cleaner

neutral terminal is identified as LINE NEUTRAL. All field wiring must

conform to applicable codes. Connections should be made as shown

below.

ELECTRONIC

AIR CLEANER

OPTIONAL

ACCESSORIES

12 PIN

CONNECTOR

120 VAC

NEUTRAL

TERMINALS

120 VAC

HOT AND

PARK

TERMINALS

INTEGRATED

CONTROL

MODULE

Accessories Wiring

24 V

OLT

T

HERMOSTAT

W

IRING

NOTE:

Wire routing must not interfere with circulator blower

operation, filter removal, or routine maintenance.

Low voltage connections can be made through either the right or left

side panel. Thermostat wiring entrance holes are located in the blower

compartment. Wire routing must not to interfere with circulator blower

operation, filter removal, or routine maintenance. Refer to the follow-

ing figure for thermostat connections to the integrated control module

terminal strip.

W

W

W

Y

Y

Y

C

C

R

R

R

G

G

W

Y

C

R

G

HEATING

ROOM

THERMOSTAT

HEATING AND

COOLING ROOM

THERMOSTAT

FURNACE

FURNACE

REMOTE

CONDENSING

UNIT

Thermostat Diagram

This furnace is equipped with a 40 VA transformer to facilitate use with

most cooling equipment. Consult the wiring diagram, located on the

blower compartment door, for further details of 115 Volt and 24 Volt

wiring.

GME95/AMEH96 F

URNACE

WITH

2-S

TAGE

C

ONDENSER

F

IELD

W

IRING

The GME95/AMEH96 model furnaces may be used with a 2-stage

outdoor air conditioner. A two stage cooling/single stage gas heat ther-

mostat is required, in addition to a field supplied relay. The relay must

have a 24VAC coil and contacts rated for up to 1 horse power at

125VAC.

1.

Install the field supplied relay on the control mounting panel

near the furnace ignition control. The relay should be installed

such that the motor leads will reach the relay contact terminals.

2.

Connect the “Y2” (high stage cool) thermostat terminal to one

coil terminal of the field supplied relay. Connect the other field

supplied relay coil terminal to the “C” terminal on the furnace

ignition control. Typical 18AWG thermostat wire may be used.

3.

Connect the common terminal of the field supplied relay to the

“LINE-H” terminal on the furnace ignition control. Use wiring

having copper conductors only and a temperature rating of at

least 105°C.

4.

Using the GME95/AMEH96 airflow tables in this manual,

determine the motor speed tap needed to deliver the required

high stage cooling airflow. Connect the selected motor speed

tap to the normally open terminal on the field supplied relay.

Use wiring having copper conductors only and a temperature

rating of at least 105°C.

5.

See the following wiring schematic.

Содержание ACSH96

Страница 53: ...53 THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 54: ...54 THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 55: ...55 THIS PAGE LEFT INTENTIONALLY BLANK...