All gas piping must be installed to comply with local codes, or, in the absence of local

codes, with the latest edition of the National Fuel Gas Code ANSI Z223.1.

Unions in gas lines shall be of ground joint type. Compounds used on threaded joints of

gas piping must be resistant to the action of liquefied petroleum gas. Gas piping must be

of sufficient size to provide a minimum natural gas pressure at the appliance of 7" water

column or 11" for L.P. gases for the purpose of input adjustment. The maximum inlet gas

pressure to the unit must not exceed 10" for natural gas, and 13" for L.P. gases. If this

unit is to be supplied with L.P. gas (bottled propane) the tank or bottle supplying the gas

must have a regulator that reduces the gas pressure to between 11 and 13 inches water

column. The control will not operate with gas line pressure directly from the tank and may

leak gas due to this excessive pressure.

DANGER:

OPERATION OF THIS UNIT ON L.P. GAS WITHOUT AN APPROVED

REGULATOR AT THE SUPPLY CONTAINER WILL LEAD TO GAS LEAKS AT THE

CONTROL WITH POSSIBLE FIRE OR EXPLOSION.

Include a manual shut-off valve and union in the line so the control or heater may be

disconnected for servicing. Include a drip leg and a plugged 1/8" N.P.T. tapping into the

line also. The tapping must be accessible for the test gauge connection immediately

upstream of the gas supply connection to the unit. Use a soap and water solution or

liquid gas leak detector to coat each joint in the piping system and look for bubbles

which indicate gas leaks. Repair all gas leaks.

CAUTION:

THE APPLIANCE AND ITS APPLIANCE MAIN GAS VALVE MUST

BE DISCONNECTED FROM THE GAS SUPPLY PIPING SYSTEM DURING ANY

PRESSURE TESTING OF THAT SYSTEM AT TEST PRESSURES IN EXCESS OF

1/2 PSI (3.5 KPA).

THE APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY

CLOSING THE EQUIPMENT SHUTOFF VALVE DURING ANY PRESSURE TESTING OF

THE GAS SUPPLY PIPING SYSTEM AT TEST PRESSURES EQUAL TO OR LESS THAN

1/2 PSI (3.5 KPA).

DANGER:

DO NOT USE CANDLES, MATCHES OR OTHER IGNITION SOURCES WHEN

CHECKING FOR LEAKS. FUEL GASES ARE VERY FLAMMABLE AND IN CERTAIN

CONCENTRATIONS, EXPLOSIVE. CHECKING FOR LEAKS WITH AN OPEN FLAME MAY

LEAD TO FIRE OR EXPLOSION.

GAS PIPING AND GAS PRESSURE REQUIREMENTS

5

Содержание LFP9618

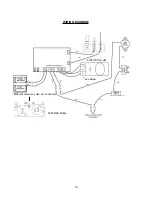

Страница 13: ...13 WIRING DIAGRAM see below 6003 3V Model Different valve may use pin connector 6003V 6K Model ...

Страница 17: ...17 ...

Страница 19: ...19 Inc ...