34

©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the

right to amend specifications without notice or obligation.

OPERATION

PC2_ or PC1_ pumps should only be used when working from open water or a tank

feed. NEVER USE CAFS WITH A PRESSURE FEED INTO THE EYE OF THE PUMP.

Problems will occur with the water / air pressure ratio, should pressurised (hydrant)

water supply be applied directly to the suction tube. Hydrant supply may only be used to

maintain the water level in the vehicle tank.

Minimum idle speed:

To prevent unnecessary operation of the pump priming system,

maintain an idle speed of 900-1000rpm.

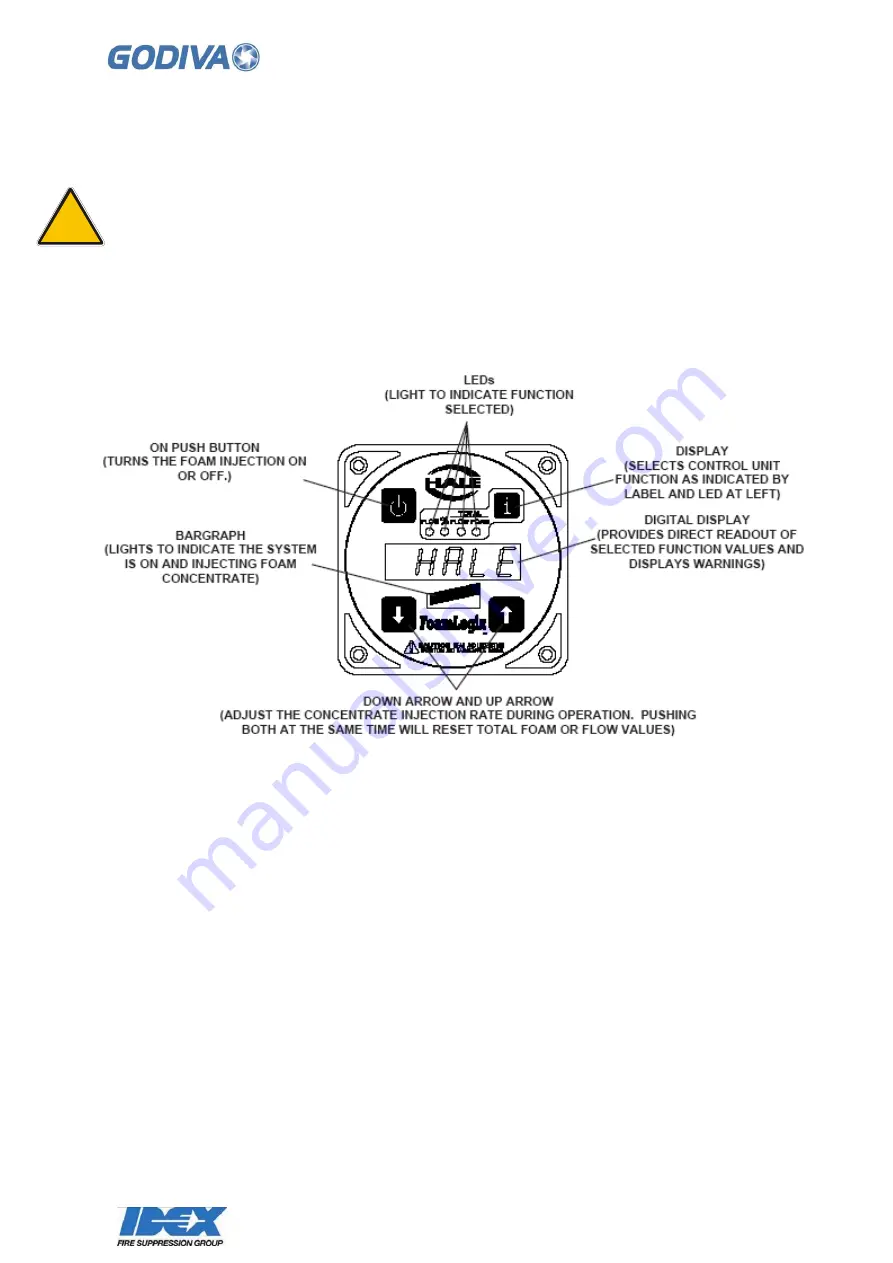

FoamLogix Control Panel Functions

Commissioning / Start-Up Procedure

1.

Check that all the necessary connections have been correctly made.

2.

Ensure that the compressor, pump gearbox and bearing housing are filled with the

correct oil type and quantity.

3.

Run the water pump at 2-3 bar with compressor engaged.

4.

Run the compressor for 30 seconds to allow oil to circulate.

5.

Stop unit and check compressor oil level

– top up if necessary.

6.

Turn the bypass valve on the FoamLogix to bypass and provide a suitable

receptacle to collect the foam, agent.

7.

Ensure that there is sufficient foam agent in the tank(s). For

FoamLogix 3.3 or 5.0

select tank

A

!