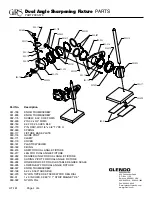

Page 3 of 4

LIT-181

CALIBRATION

Step 1: Loosen the two bolts, about a full turn each, in the lower

jaw with a hex wrench. Do not remove.

Step 2: Make sure the bolts are

loose enough that you

can “wiggle” the lower

jaw with your fingers.

Step 3: Insert the small round

calibration pin (included

with the fixture) and

slowly start to turn the

thumbscrew to tighten

it into the jaws. While

turning the thumbscrew,

continuously wiggle

the lower jaw. This

will make the lower

jaw “seat” in the

proper location on the

calibration pin.

Step 4: Once you have the

calibration pin seated

and snugged down,

tighten the lower jaw

bolts with the hex

wrench. NOTE: Use

the long end of the

hex wrench in the bolt

head and turn with the

short end to prevent

over tightening. Over

tightening will damage

the fixture.

Step 5: Loosen the “DEGREE”

ring with the small hex

wrench until you can

easily turn the degree

ring independently

from the jaw head.

Now, remove the round

calibration pin and

replace it with a square

graver. A GRS GlenSteel

graver will work great.

Step 6: Place a ceramic lap

wheel on your Power

Hone for a smooth flat

surface. TIP: If you don’t

have a ceramic lap use a

fine grit diamond wheel and turn it up-side-down and use

the smooth backside. Place the dual angle fixture head

on the post stand and position the square graver so that a

side of it is pressed flat against the wheel. While holding

the graver flat, turn the degree ring and register the 45°

mark to the center line mark and tighten the degree ring

set screw. Now, when you turn the fixture head to 0° or

90° the graver is calibrated and in the correct position.

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6