13

26. Replace the front portion of the connecting rod (20) and plunger rod/ crosshead assembly (22) by press-fitting

the crosshead pin (23). Make sure to insert the beveled edge of the crosshead pin into crosshead. If the

crosshead has a mark, install pin from marked side.

The crosshead pin (23) should not extend beyond

either side of the crosshead (22) in order to prevent damage to the crosshead bore of the crankcase (1).

27. Place each crosshead/ plunger assembly into the pump making sure that all of the parts are well oiled before

insertion into the crankcase (1).

Notice that the connecting rod (20) halves are numbered or colored.

Connecting rods must be positioned with their numbers or colors on the upper left-hand side, in the

same numerical sequence as when they were removed.

28. Replace near side bearing (15) on crankshaft by using the Giant Bearing Tool and mallet to tap into place.

Take the crankshaft (18) end with the bearing (15) and insert the other end through the bearing housing and

tap with a rubber mallet until the bearing is seated.

29. When reassembling the connecting rods (20), note that the connecting rod halves are numbered or colored

and that the numbers or colors must be matched and aligned. Torque the connecting rod bolts to 125-150 in.-

lbs.

30. Insert the near side crankshaft oil seal (14) with the Giant Bearing Tool making sure it is firmly seated and

well oiled. Replace the bearing cover (12) and o-ring (13) and tighten securely.

See instructions above for re-installing fluid end onto the gear end.

31. Fill the P55W / P56W crankcase (1) with 14 oz. of Giant Industries’ oil and check the oil level with the

dipstick (5). Proper level is center of two lines. Reinstall the pump into your system.

Содержание P55W

Страница 6: ...6 Exploded View P55W P56W P56W HK P56HT ...

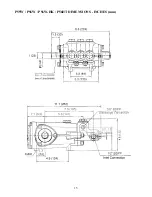

Страница 15: ...15 P55W P56W P56W HK P56HT DIMENSIONS INCHES mm ...