3

Horsepower Ratings:

We recommend a 1.15 service factor be specified when selecting an electric motor as the power source.

To compute electric motor

horsepower required, use the following formula: HP = (GPM X PSI) / 1450.

The formula to determine the horsepower required for a gas engine is: HP = (GPM X PSI) / 1150.

The formula to determine the horsepower required for a diesel engine is: HP = (GPM X PSI) / 1250.

For the Application of a Hydraulic Motor:

To Determine the Torque of a Hydraulic Motor -- (GPM x PSI x 36.77) / RPM = Torque (in-lbs)

Calculating RPM / GPM of Pump:

A pump must be connected to an electric motor or gas or diesel engine with the correct ratio of pulleys

and belts to attain the required speed and GPM. The use of a Variable Frequency Drive (VFD) may also

be used to control the RPM of a properly sized electric motor when variable flows are required.

(Max. Pump RPM / Rated Pump GPM) x Required Pump GPM =

Required Pump RPM

To calc

ulate a pulley diameter one (1) pulley diameter and the required pump RPM must be known:

(Pump RPM x Pump Pulley Diameter) / Motor RPM = Motor Pulley Diameter

(Motor RPM x Motor Pulley Diameter) / Pump RPM = Pump Pulley Diameter

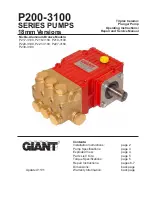

Materials Used for P200-3100 Pumps:

Manifold

........

Nickle-Aluminum Bronze

Plungers .......

Solid Ceramic Oxide

Valves .............

316 Stainless Steel

Seals...............

Nitrile with Fabric Reinforcing

Gear End

......

Anodized Aluminum

Common Specifications:

Max. Inlet Pressure

..............

145 PSI (10 Bar)

Crankshaft Diameter

............

0.94” (24mm)

Oil Capacity (short)

..............

7.5 fl. oz. (0.2 L)

Oil Capacity (extended)

.......

9.0 fl. oz. (0.3 L)

Inlet Ports ............................

(2) 1/2” BSP

Discharge Ports

...................

(2) 3/8” BSP

Weight

.................................

13.4 lbs (6.0 kg)

Shaft Rotation

Top of Pulley Towards Fluid End

U.S. Measurements

Max. Flow

Maximum

Pressure

Max.

Speed

Power

Req'd.

Max.

Temperature

Plunger

Diameter

Stroke

NPSH

Required

Model

GPM

PSI

RPM

BHP

F

in

in

Ft-Head

P230-3100

1.1

2000

1750

1.5

86

0.71

0.13

n/a

P217-3100

1.85

2000

1750

2.6

86

0.71

0.22

n/a

P227-3100

2.1

2000

1750

2.9

86

0.71

0.25

n/a

P230-3100

2.1

2000

3450

2.9

86

0.71

0.13

n/a

P221-3100

2.34

2000

1750

3.32

86

0.71

0.28

n/a

P218-3100

3.4

2000

1750

4.7

86

0.71

0.39

21.0

P217-3100

3.6

2000

3450

5

86

0.71

0.42

n/a

P227-3100

3.8

2000

3450

5.2

86

0.71

0.25

n/a

P219-3100

4.2

2000

1750

5.8

86

0.71

0.49

21.0

P220-3100

4.7

2000

1750

6.5

86

0.71

0.56

21.6

Metric Measurements

Max. Flow

Maximum

Pressure

Max.

Speed

Power

Req'd.

Max.

Temperature

Plunger

Diameter

Stroke

NPSH

Required

Model

L/min

Bar

RPM

kW

C

mm

mm

mWs

P230-3100

4.2

140

1750

2.0

30

18

3.4

n/a

P217-3100

7.0

140

1750

3.5

30

18

5.5

n/a

P227-3100

7.9

140

1750

3.9

30

18

6.3

n/a

P230-3100

7.9

140

3450

3.9

30

18

3.4

n/a

P221-3100

8.9

140

1750

4.5

30

18

7

n/a

P218-3100

12.9

140

1750

6.3

30

18

10

6.4

P217-3100

13.6

140

3450

6.7

30

18

5.5

n/a

P227-3100

14.4

140

3450

7.0

30

18

6.3

n/a

P219-3100

15.9

140

1750

7.8

30

18

12.4

6.4

P220-3100

17.8

140

1750

8.7

30

18

14.1

6.6

P200-3100 Series - 18mm Versions- Pump Specifications

Содержание P217-3100

Страница 4: ...4 Exploded View P200A 3100 Series...