3

Consult the factory for special requirements that

must be met if the pump is to operate beyond

one or more of the limits specified above.

Horsepower Ratings:

We recommend a 1.15 service factor be specified when selecting an electric motor as the power source.

To compute electric motor horsepower required, use the following formula: HP = (GPM X PSI) / 1450.

The formula to determine the horsepower required for a gas engine is: HP = (GPM X PSI) / 1150.

The formula to determine the horsepower required for a diesel engine is: HP = (GPM X PSI) / 1250.

For the Application of a Hydraulic Motor:

To Determine the Torque of a Hydraulic Motor -- (GPM x PSI x 36.77) / RPM = Torque (in-lbs)

Calculating RPM / GPM of Pump:

A pump must be connected to an electric motor or gas or diesel engine with the correct ratio of pulleys

and belts to attain the required speed and GPM. The use of a Variable Frequency Drive (VFD) may also

be used to control the RPM of a properly sized electric mot

or when variable flows are required.

(Max. Pump RPM / Rated Pump GPM) x Required Pump GPM =

Required Pump RPM

To calculate a pulley diameter one (1) pulley diameter and the required pump RPM must be known:

(Pump RPM x Pump Pulley Diameter) / Motor RPM = Motor Pulley Diameter

(Motor RPM x Motor Pulley Diameter) / Pump RPM = Pump Pulley Diameter

Common Specifications:

Inlet Pressure ..

-4.35 to 145 PSI (-0.3 to 10 Bar)

Max. Temperature ..................140

o

F (60

o

C)

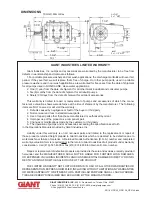

Crankshaft Diameter..............

1.38” (35mm)

Crankcase Oil Capacity .........1.2 Gal. (4.6 L)

Inlet Ports ..............................

(2) 1-1/2” NPT

Discharge Ports .....................

(2) 1” NPT

Stroke ....................................

1.81” (46mm)

Weight ...................................179 lbs (81kg)

Shaft Rotation ..Top of Pulley Toward Fluid End

Materials Used for MP Pumps:

Manifold ........ Nickel-Plated Spheroidal Cast Iron

Plungers ....... Solid Ceramic Oxide

Valves ........... Duplex Steel/Plastic Retainer

Seals............. Nitrile with Fabric Reinforcing

Gear End ...... Spheroidal Cast Iron

GP5100 SERIES PUMP SPECIFICATIONS

Max.

Flow

Max.

Pressure

Max.

Speed

Power

Req’d.

Max.

Temp.

Plunger

Diameter

NPSH

Required

Model

GPM

PSI

RPM

HP

F

in

Ft-Head

GP5132

27.7

2900

1000

57

140

1.26

27.9

GP5132*

40

3000

1444

83

140

1.26

27.9

GP5136

33.8

2320

910

56

140

1.42

27.9

GP5142

40.4

1885

800

54.4

140

1.65

N/A

GP5145

43.5

1450

750

45

140

1.77

29.5

Max.

Flow

Max.

Pressure

Max.

Speed

Power

Req’d.

Max.

Temp.

Plunger

Diameter

NPSH

Required

Model

L/min

Bar

RPM

kW

C

mm

mWs

GP5132

104.9

200

1000

42.8

60

32

8.5

GP5132*

151.4

207

1444

61.9

60

32

8.5

GP5136

127.8

160

910

41.8

60

36

8.5

GP5142

153.0

130

800

40.6

60

42

N/A

GP5145

164.6

100

750

33.6

60

45

9.0

* Intermittent rating

* Intermittent duty only.