T3

TWINMOT

- 7-

Installation instructions for engine

swap:

• If the engine is not in the correct position for the

installation, connect the plug and press the buttons

2 and 6 on the hand switch. The motor will move into

position for installation.

• For security reasons again pull the plug from the

socket. For an easy installation, place the bed frame

upside down so the steel pipes face upwards. Now

fi rmly press the engine through the nail-shaped

projections until the tubes remain in the “u” form gap.

• Make sure the symbol for the back on the engine

shows to the head of the bed frame. At the T1 the

holes in the top of the engine are closed on the

tubes with sliding covers, which fi t into the center

of the slot.

• After completing the installation, check that the

remote cable is properly plugged in and is strain-re-

lieved (see drawing). Now place the slatted frame on

the bed frame and connect the plug, so the internal

energy storage can recharge itself.

• Then place the battery.

Emergency lowering:

So you can leave the slatted frame in a reclining po-

sition at power failure, the bed has special equipment

connected to an integrated of 9-V alkaline battery,

which is automatically activated when pressing the

button 2 and 6. The download speed is reduced.

Although the battery can hold several emergency

descents, we recommend changing after each

descent, or after a maximum of three years, due to

the deterioration of the same.

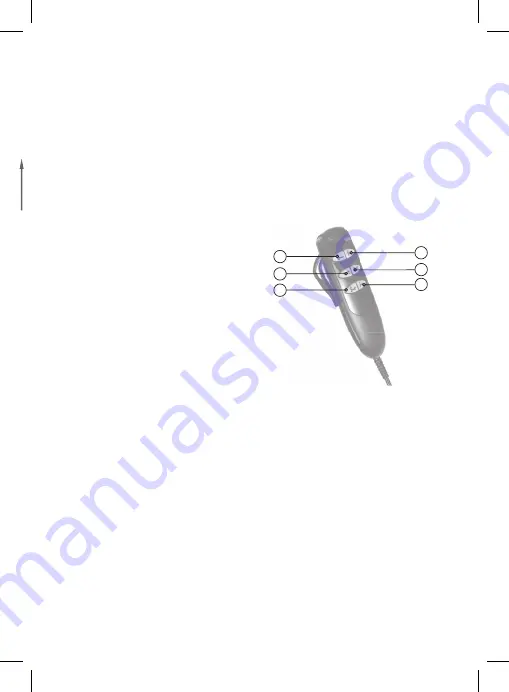

Hand switch (functions):

1 – Back part up

2 – Back part down

3 – Foot and back part up

4 – Foot and back part down

5 – Foot part up

6 – Foot part down

Technical data:

Connecting power supply 220-240 Volt AC

50/60 Hz.

The engine works with a DC voltage of 24 V DC.

Maximum connection time 15% with continuous

operation is 2 minutes.

Operating voltage for the hand switch is 24 V DC.

Power required, depending on load and models:

30-300 W.

3

5

4

6

1

2