© 2020 Genesis Attachments, LLC

Genesis Rail Breaker GRB 30 43

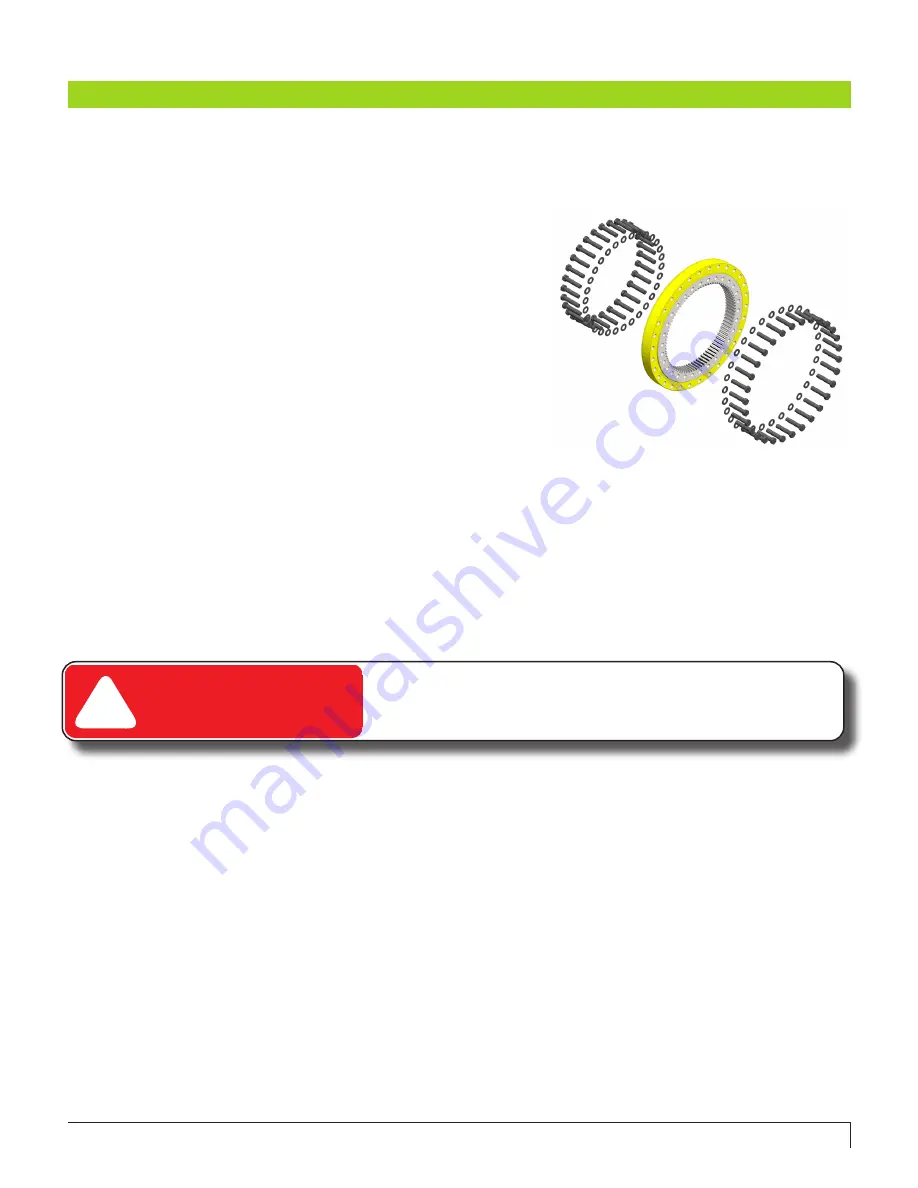

Visually check slewing ring (rotation bearing) bolts every eight hours of operation and replace ev-

ery 2000 hours. Do not reuse or re-torque these bolts.

Immediately replace a loose or broken bolt, and replace the bolts on either side of it.

The bolts that secure the slewing ring are critical to safe

operation of the attachment. Improper bolt torques may

cause the bolts to fail and allow the attachment to break

free. This may result in serious personal injury and

equipment damage. Improper torques will also cause

uneven wear on the slewing ring.

Rotating components must be greased daily. Grease

fittings are located on the outside of the slewing ring

and on the inside of the rotating head assembly. Grease

locations are marked with decals.

Grease each fitting. Rotate the attachment two full rotations after greasing each fitting.

For normal conditions above 32˚ F (0˚ C), use a lithium-based, premium grade 2 extreme pressure

grease. For temperatures below 32˚ F, a grade 0 grease is recommended.

SLEWING RING MAINTENANCE

!

DANGER

Stand clear when the attachment is being rotated. Always

stay in clear view of the operator.