ASSEMBLY INSTRUCTIONS

All unpainted surfaces are covered with a protective

coating that prevents rust from forming during shipping and

storage. Peel off the plastic cover from the table and remove

this protective coating by rubbing with a rag dipped in

kerosene, mineral spirits or paint thinner. (Dispose of potentially

flammable solvent-soaked rags according to manufacturer’s

safety recommendations.)

A putty knife, held flat to avoid scratching the surface, may also

be used to scrape off the coating followed by clean-up with

solvent. Avoid rubbing the machine’s painted surfaces, as many

solvent-based products will remove paint.

For optimum performance from your machine, make sure you

clean all metal surfaces of the spindles with a mild solvent or

kerosene.

To prevent rust, apply a light coating of paste wax or regular applications of General International “Top Saver” item

# GC-010 or similar after-market protectants to the table surface.

Be sure to work in a well ventilated area for the

entire clean up process.

Before starting the clean up process make sure the

machine is not plugged into a power source. Failure

to comply may lead injury or cause damage to the

machine.

CLEAN UP

The unit should be installed on a flat, sturdy and stable surface able to support the weight of the machine.

Never install the machine over the edge of a table

or workbench.

Never lift the machine by the table; hold and lift

from the insets on the cabinet.

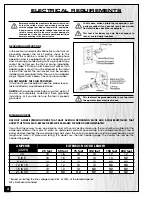

Make sure that the switch is in “OFF” position and that the power

cord is unplugged & install the red stop switch cover plate.

7

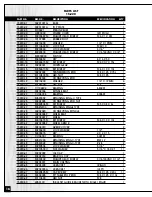

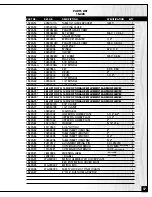

Содержание 15-220

Страница 15: ...15 Mod le 15 220...