4 - 24

Maintenance and Repair

4.15

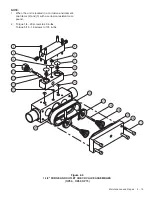

Remote Flow Restrictor

Maintenance

(Model OP250 only)

WARNING!

Ensure that the dryer is de-energized, valve isolated,

and fully depressurized before attempting to remove

or disassemble any dryer component or subassembly.

Failure to do so may result in serious personal injury

and/or equipment damage.

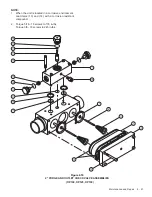

1.

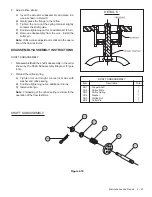

Remove muffler as follows:

a) Provide adequate support for muffler and flow

restrictor assembly. Remove flow restrictor as-

sembly from lower flange by equally loosening

flange bolts. Ensure that the method of support

is prepared to accept the muffler and flow

restrictor's full weight when the last bolt is re-

moved (see following CAUTION).

CAUTION: Exercise caution when lowering muf-

fler and flow restrictor to prevent damaging control

tubing and the Purge Pressure Indicator.

2.

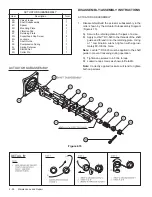

Remove, clean and inspect the "spring and orifice-

type" flow restrictor. Install a new flow restrictor if

damage is noted.

IMPORTANT: When installing Flow Restrictor, its

springs must be fully seated in the spring receptacle.

This must be accomplished for proper operation.

3.

Reinstall muffler and flow restrictor assembly in the

reverse order of removal.

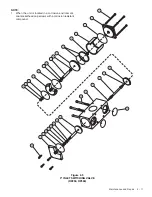

Figure 4.12

Содержание Optima OP100

Страница 48: ......

Страница 58: ...A 2 Appendix A Purge Curves CRITICAL ORIFICE CALIBRATION CURVE OP15 Orifice Dia 156 Gas Air Temp 100 F CD 65 ...

Страница 59: ...Appendix A Purge Curves A 3 CRITICAL ORIFICE CALIBRATION CURVE OP25 Orifice Dia 219 Gas Air Temp 100 F CD 65 ...

Страница 61: ...Appendix A Purge Curves A 5 CRITICAL ORIFICE CALIBRATION CURVE OP50 Orifice Dia 281 Gas Air Temp 100 F CD 65 ...

Страница 63: ...Appendix A Purge Curves A 7 CRITICAL ORIFICE CALIBRATION CURVE OP100 Orifice Dia 406 Gas Air Temp 100 F CD 65 ...

Страница 65: ...Appendix A Purge Curves A 9 CRITICAL ORIFICE CALIBRATION CURVE OP200 Orifice Dia 563 Gas Air Temp 100 F CD 65 ...

Страница 68: ......