Maintenance and Repair

4 - 3

Activated Alumina

Model

(lbs. per chamber)

OPD-4

OPD-25

OP15

24

——

OP25

42

——

OP30

72

——

OP40

72

——

OP50

92

——

OP60

145

——

OP75

145

——

OP100

192

——

OP125

239

——

OP150

318

——

OP200

416

——

OP250

540

——

OP300

675

——

OP400

875

75

OP500

1350

150

Table 4.1

DESICCANT REQUIREMENTS

For Dryer Models OP15 through OP300

a) Fill each chamber with OPD-4 (4mm bead) des-

iccant until the specified quantity has been in-

stalled. Light tapping on the chamber sides with

a soft-face mallet should yield additional free

space to allow installation of the specified quan-

tity. DO NOT TAMP OR RAM DESICCANT.

For Dryer Models OP400 and OP500

a) Install the specified quantity of OPD-25 (1/4"

bead) desiccant.

b) Level layer of OPD-25.

c)

Finish filling each chamber with OPD-4 (4mm

bead) desiccant until the specified quantity has

been installed. Light tapping on the chamber

sides with a soft-face mallet should yield addi-

tional free space to allow installation of the speci-

fied quantity. Do Not Tamp Or Ram Desiccant.

Note: Do not be alarmed if the specified quantity

of desiccant cannot be installed in each chamber.

Desiccant levels will settle after approximately

two to three weeks of normal operation. Follow-

ing this “settling” period, desiccant should be

added as necessary to return levels to BOTTOM

of each chamber’s retaining screen (when in-

stalled).

9.

Clean the fill port, fill port plug threads, or fill port

flanges on each desiccant chamber. Apply TFE tape

to fill port plug threads. Re-install the fill port plug or

fill port flange in each desiccant chamber, and torque

drain port plugs or flange bolts to a reasonable limit.

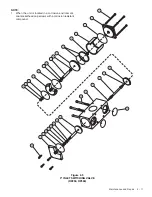

4.3

Filter Element Replacement

Coalescing prefilters and particulate afterfilters are in-

cluded with all Optima Series Dryers. The filter elements

should be replaced when the differential pressure gauge

on top of the filter reads 7 to 10 psid, or once a year,

whichever comes first. Refer to Appendix B for the re-

placement element part numbers. Replace elements in

accordance with the following instructions.

Dryer Models OP15 through OP250

WARNING!

Ensure that the Dryer and any associated Prefilters

and Afterfilters are valve isolated and fully depressur-

ized before attempting to remove or disassemble any

components or subassemblies. Failure to do so may

result in serious personal injury and/or equipment

damage.

1.

Isolate the filter by opening the system bypass valve

(refer to Figure 2.1, page 2-2), and closing both inlet

and outlet isolation valves.

2.

Open the service valve to vent the filter to atmo-

spheric pressure.

3.

Disconnect drain lines at manual and automatic drain

valves (if installed).

WARNING!

A "hissing" sound while the bowl is being removed

indicates the filter has not been properly depressur-

ized. DO NOT continue to remove the bowl until the

filter has been completely vented to atmospheric pres-

sure.

CAUTION: Filter bowls may be heavy. Caution should be

taken when removing the bowl.

4.

Remove the bottom bowl by unscrewing it from the

head. A strap wrench may be needed.

5.

Remove the element from the filter head with a brisk

downward pull, or by working the element back and

forth until it snap frees. Discard the element in accor-

dance with applicable regulations. Used elements

typically hold contaminants such as compressor lubri-

cants and particulate matter.

Note: The element may be unsnapped by differential

pressure in normal operation. This will not affect filtration,

as the O-ring on the element maintains a positive seal.

6.

Clean accumulated debris from the bowl with soap

and water, and dry thoroughly.

Содержание Optima OP100

Страница 48: ......

Страница 58: ...A 2 Appendix A Purge Curves CRITICAL ORIFICE CALIBRATION CURVE OP15 Orifice Dia 156 Gas Air Temp 100 F CD 65 ...

Страница 59: ...Appendix A Purge Curves A 3 CRITICAL ORIFICE CALIBRATION CURVE OP25 Orifice Dia 219 Gas Air Temp 100 F CD 65 ...

Страница 61: ...Appendix A Purge Curves A 5 CRITICAL ORIFICE CALIBRATION CURVE OP50 Orifice Dia 281 Gas Air Temp 100 F CD 65 ...

Страница 63: ...Appendix A Purge Curves A 7 CRITICAL ORIFICE CALIBRATION CURVE OP100 Orifice Dia 406 Gas Air Temp 100 F CD 65 ...

Страница 65: ...Appendix A Purge Curves A 9 CRITICAL ORIFICE CALIBRATION CURVE OP200 Orifice Dia 563 Gas Air Temp 100 F CD 65 ...

Страница 68: ......