ENGLISH

13

170130

3. Press in the blade lock button located at the front of the motor housing,

and keep it depressed.

4.

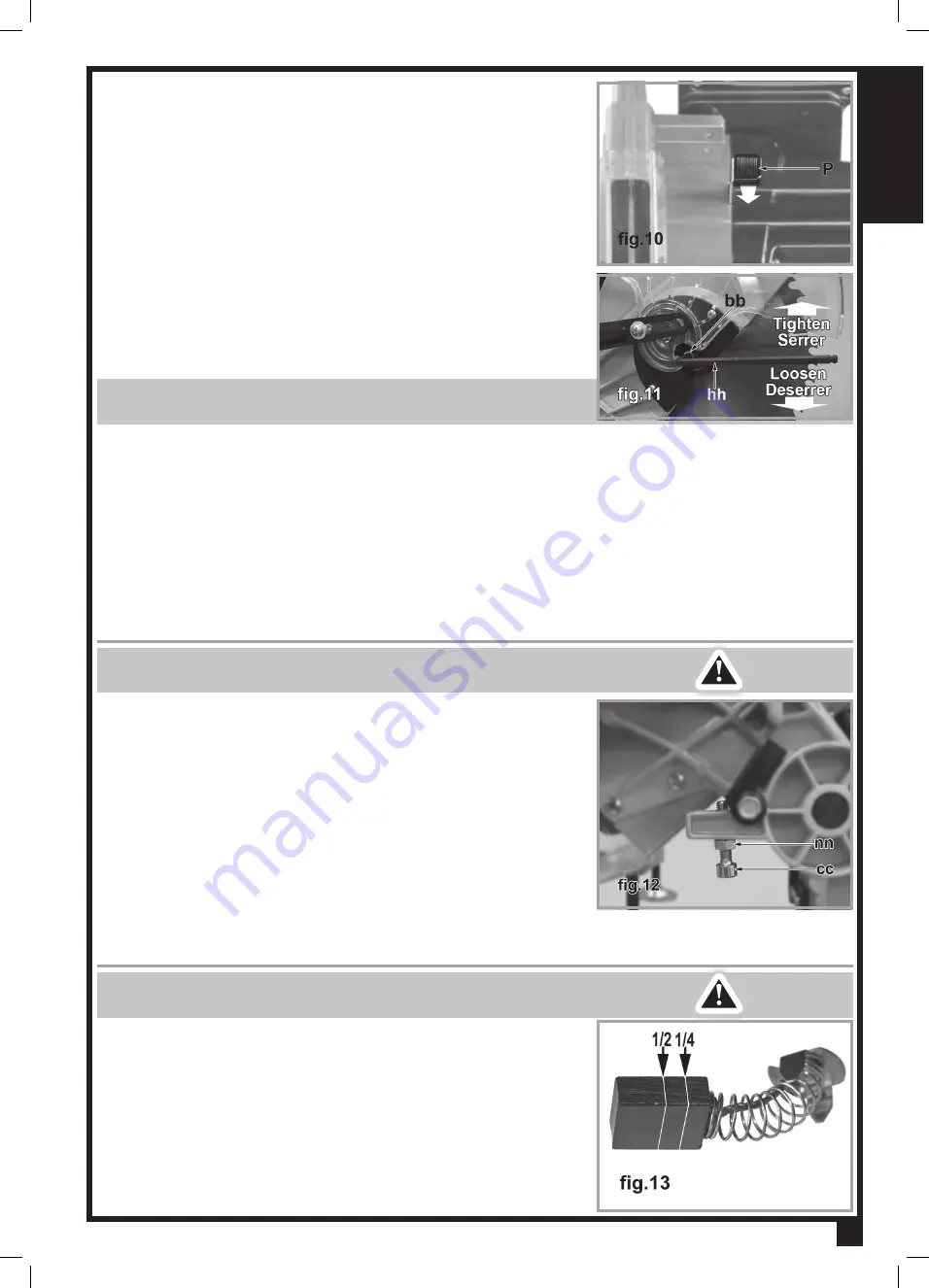

With a 6 mm hex wrench (hh, fig.11), loosen the blade bolt (turning it

clockwise) and remove it.

NOTE:

this bolt has a left hand thread.

To remove it, you must turn it clockwise.

5.

Remove the underlying washer, the outer flange and the old saw blade.

6.

Clean the bolt, washer, inner and outer flanges.

7. Place a new saw blade with the teeth pointing in the direction of rotation

onto the inner flange and saw blade shaft. (See the arrow on the upper

blade guard).

8.

Place the outer flange on the saw blade shaft.

9. Engage the lock knob, mount the washer and blade bolt. Tighten it by

turning it counter-clockwise.

10. Lower the saw blade guard.

ADJUSTING CUTTING CAPACITY

WARNING:

Before any adjustments, disconnect the machine from the

power source.

This machine has been set by the manufacturer at the maximum cutting

capacity for a 10” saw blade. If the diameter of the blade diminishes

because of sharpening, adjust the machine per the following instructions:

1. Push the handle down completely, to its lowest position.

2.

Turn the kerf depth adjustment screw (cc, fig.12) with a 5 mm hex wrench

so that the saw blade teeth are slightly below the table surface in line with

the front surface of the fence.

3. Be sure the saw is disconnected from power.

Turn the saw blade

by hand, and pressing the handle to its lowest position, check the saw

blade does not contact anything below the table. If necessary, you can

adjust upward very slightly.

4.

Tighten the hex locking nut (nn, fig.12) on the shank of the kerf depth

adjustment screw to lock its setting.

REPLACING THE CARBON BRUSHES

WARNING:

Prior to inspection or saw maintenance, turn off power

switch and disconnect plug from power source.

1. Remove and check the carbon brushes regularly.

2. Use a screwdriver to remove the brush holder caps.

3. Replace brushes when they are excessively chipped or wear down to

the limit (1/4) mark (fig.4).

4. Take out the worn carbon brushes, insert new ones and secure the

brush holder caps.

5. Both carbon brushes should be replaced at the same time.

6. Keep the carbon brushes clean and free to slip in the holders.

Содержание MS3003

Страница 16: ...ENGLISH 16...