4

Section 3 — Operation

ATS “HS” Type Transfer Switch

Conductor sizes must be adequate to handle the

maximum current to which they will be subjected to,

based on the 75°C column of tables, charts, etc. used

to size conductors. The installation must comply fully

with all applicable codes, standards and regulations.

Before connecting wiring cables to terminals, remove

any surface oxides from the cable ends with a wire

brush. All power cables must enter the enclosure

through the knockouts. If not using the knockouts,

entry must be at or below knockouts. If ALUMINUM

conductors are used, apply corrosion inhibitor to

conductors. Tighten terminal lugs to the torque

values as noted in Section 1.2.2, and on the decal

located on the inside of the door. After tightening ter-

minal lugs, carefully wipe away any excess corrosion

inhibitor.

Use a torque wrench to tighten the conduc-

tors, being sure not to overtighten, or damage

to the switch base could occur. If not tightened

enough, a loose connection would result, caus-

ing excess heat which could damage the switch

base.

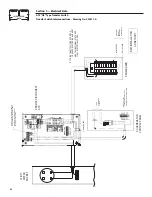

Connect power source load conductors to clearly

marked transfer mechanism terminal lugs as fol-

lows

1. Connect UTILITY (NORMAL) power source cables

to circuit breaker.

2. Connect EMERGENCY (STANDBY) source power

cables to transfer switch terminals E1, E2.

3. Connect customer LOAD leads to switch termi-

nals T1, T2.

Conductors must be properly supported, of approved

insulative qualities, protected by approved conduit,

and of the correct wire gauge size in accordance with

applicable codes.

Be sure to maintain proper electrical clearance

between live metal parts and grounded metal. Allow

at least 1/2 inch for 100-400 amp circuits.

2.5

CONNECTING START CIRCUIT

WIRES

Control system interconnections consist of N1 and

N2, T1 and T2, and leads 23 and 194. Control system

interconnection leads must be run in a conduit that

is separate from the AC power lead. Recommended

wire gauge sizes for this wiring depends on the length

of the wire, as recommended below:

MAXIMUM WIRE LENGTH

RECOMMENDED WIRE

SIZE

460 feet (140m)

No. 18 AWG.

461 to 730 feet (223m)

No. 16 AWG.

731 to 1,160 feet (354m)

No. 14 AWG.

1,160 to 1,850 feet (565m)

No. 12 AWG.

NOTE:

When this ATS is used with an air-cooled genera-

tor, the LOAD 1 and LOAD 2 wires are not used.

3.1

FUNCTIONAL TESTS AND

ADJUSTMENTS

Following transfer switch installation and inter-

connection, inspect the entire installation care-

fully. A competent, qualified electrician should

inspect it. The installation should comply strictly

with all applicable codes, standards, and regula-

tions. When absolutely certain the installation is

proper and correct, complete a functional test of

the system.

Perform functional tests in the exact order pre-

sented in this manual, or damage could be done

to the switch.

IMPORTANT: Before proceeding with functional tests,

read and make sure all instructions and information

in this section are understood. Also read the infor-

mation and instructions of labels and decals affixed

to the switch. Note any options or accessories that

might be installed and review their operation.

3.2 MANUAL OPERATION

DANGER

Do NOT manually transfer under load.

Disconnect transfer switch from all power sourc-

es by approved means, such as the main circuit

breaker(s).

A manual HANDLE is shipped with the transfer

switch. Manual operation must be checked BEFORE

the transfer switch is operated electrically. To check

manual operation, proceed as follows:

1. Turn the generator’s AUTO/OFF/MANUAL switch

to OFF.

2. Turn OFF both UTILITY (service disconnect cir-

cuit breaker) and EMERGENCY (generator main

line to circuit breaker) power supplies to the

transfer switch.

3. Turn the GENERATOR DISCONNECT SWITCH

to the OFF position.

4. Note position of transfer mechanism main con-

tacts by observing the moveable contact carrier

arm. This can be viewed through the long narrow

slot in the inside cover of the ATS. The top of the

moveable contact carrier arm is yellow to be eas-

ily identified.

• Manual operation handle in the UP position -

LOAD terminals (T1, T2) are connected to UTIL-

ITY terminals (N1, N2).

Содержание 004945-1

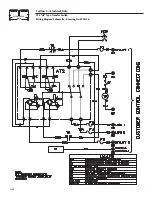

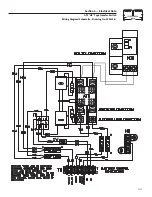

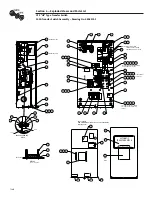

Страница 12: ...10 Section 5 Electrical Data ATS HS Type Transfer Switch Wiring Diagram Schematic Drawing No 0F0015 A...

Страница 13: ...11 Section 5 Electrical Data ATS HS Type Transfer Switch Wiring Diagram Schematic Drawing No 0F0015 A...

Страница 18: ...16 Generac Power Systems Inc Section 7 Notes ATS HS Type Transfer Switch...

Страница 19: ...Generac Power Systems Inc 17 Section 7 Notes ATS HS Type Transfer Switch...