3

MAINTENANCE

3.1

Spare parts manual

Hint!

A complete spare parts overview is available as a separate manual.

Download the parts list manual via GEA website or consult your sales

representative.

3.2

Post start-up maintenance

After the compressor has run for the initial 100 operating hours:

i.

Drain the oil and refill the compressor with the correct amount of fresh oil.

ii.

Replace the running oil discharge filter element with the “permanent“ filter

element in accordance with the filter replacement instructions.

iii.

Inspect suction gas filter (refer to the Compressor Service Instruction

Manual).

iv.

Exchange or clean oil suction filter element.

v.

Check the compressor shaft seal for leakage. If excessive (more than 1 cc/hr)

contact your compressor supplier

vi.

Retighten the coupling mounting bolts with the torque settings as given by the

coupling manufacturer.

vii.

Verify and if necessary, correct the torque settings of all foundation bolts as

given in Compressor Service Instruction Manual.

3.3

First maintenance

Hint!

For complete conditional service schedules and service intervals,

refer to Guideline for Conditional maintenance.

After the refrigerating plant has been modified, inspect/clean the

suction gas filter(s) and the oil filters.

After the refrigerating plant has been modified, the oil must be

changed.

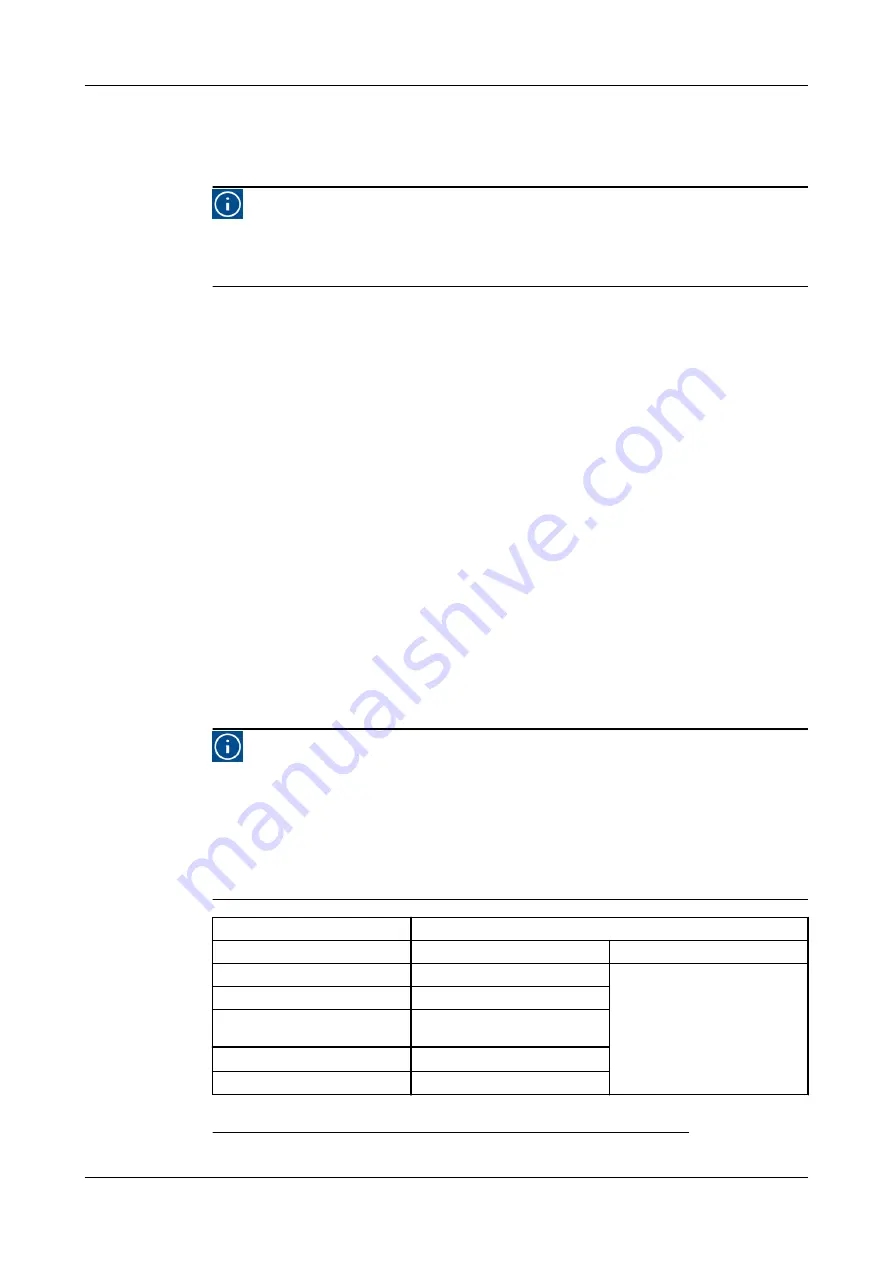

Maintenance

Number of operating hours

100

> 100

Renewal of oil discharge filter

X

refer to Guideline for Conditional

Maintenance

Inspection of suction gas filter(s)

X

Inspection of oil suction filter

(strainer)

X

Oil analysis

8

X

Inspection leakage shaft seal

X

8

Consult your oil supplier.

MAINTENANCE

Spare parts manual

P-NL-094_imm_VHS_English_13

26.07.2021

41