g) Proceed according to the points h, i and j of the

instructions for cleaning oil filters (refer to par.

9.6).

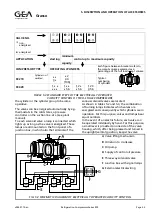

9.6 CLEANING OF OIL FILTERS

In most cases the oil filters have to be cleaned for

the first time after 50 operating hours. Besides

thorough cleaning of the gauze filter element of

the oil suction filter, the (red) paper filter element

of the oil discharge filter must be exchanged with

the blue marked element. Also after the

installation has been extended or modified, the oil

suction filter should be cleaned and the (red) oil

discharge filter renewed as if the compressor had

just been put into operation.

The time at which the next cleaning has to be

carried out highly depends on te cleanliness of the

installation.

Dirty oil (refer to par. 9.5) may cause clogging of

the (grey marked) oil suction filter. A strong

pollution of this filter is indicated by a falling oil

pressure; in this case it is necessary to clean the

filter (ultra-soon cleaning system). It is

recommended, therefore, regularly to check the

oil pressure during the first 50 operating hours.

When the filters remain practically clean, cleaning

can take place simultaneously with the other

maintenance operations.

To clean the (blue and grey marked) filters

proceed as follows:

a) Evacuate the compressor (refer to par. 9.4)

b) Unscrew the lower filter cup of both filter

housings in which event the filter elements are

released. Catch the oil in a beaker.

c) Clean the gauze filter element of the oil suction

filter only using a high frequent liquid cleaning

system (ultra soon device). After cleaning,

thorouhly dry the element; if possible, blow

through the filter element with compressed air

against the normal oil flow direction. Dip the

element into compressor oil and put aside.

d) Clean both filter cups and dry them with a

non-fibrous cloth.

e) Use the new set of seals! Remove and renew all

o-rings including the centre seal of both upper

filter housing.

f) Place the gauze filter element and a new (grey

marked) paper filter element in their

corresponding filter cups.

MIND! The paper filter element (oil discharge

filter) should be placed on the right-hand side

of the pump.

g) Screw the filter cups (do not forget the o-ring

around the filter cup) into their corresponding

filter upper housings.

h) Remove the plug on top of the suction filter

housing; fill this housing with fresh oil and

replace the plug with a new alu ring.

i) Purge the compressor (refer to par. 9.9).

j) Check the oil level and top up oil as described in

par. 9.3, topping up oil with compressor operating.

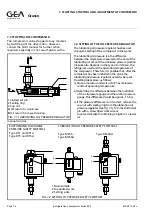

9.7 CLEANING OF THE SUCTION GAS STRAINER

a) Evacuate the compressor (refer to par. 9.4)

b) Remove the bolts from the suction strainer

cover that is most far away from the suction

line and remove the cover (if necessary, loosen

cover with a rubber or plastic hammer).

c) Pull the strainer element out of the suction

strainer housing without damaging the gauze.

d) Clean the element by rinsing it in a solvent.

Then thoroughly dry the element preferably

with compressed air.

e) Check the gauze for damage.

f) Slide the strainer element again into the

housing and fit the suction strainer cover.

Check the sealing ring for proper condition.

g) Purge the compressor (refer to par. 9.9).

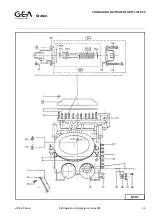

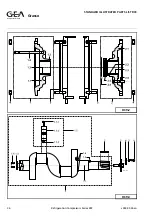

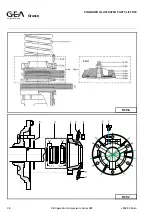

9.8 DISMOUNTING, INSPECTION AND

RE-ASSEMBLY OF SUCTION AND DISCHARGE

VALVES

The suction and discharge valves of a refrigeration

compressor are parts that are heavily loaded both

mechanically and thermally. Wear and life time of

the valves strongly depend on the working

conditions of the compressor.

A high working temperature and rapid temperature

variations shorten the life time of the valves, which,

for this reason, require regular inspection.

For dismounting, inspection and re-assembly of

the valves, proceed as follows (refer to fig. 9.1):

a) Evacuate the compressor (refer to par. 9.4).

Refrigeration Division

Grasso

9. COMPRESSOR MAINTENANCE

v003.98.11.en

Refrigeration Compressors Series RC9

Page 9.3