20

D

GB

F

E

I

96389-08.2019-DGbFEIRu

4

|

Compressor assembly

DANGER

Risk of electric shock! High voltage!

Only carry out work when the electrical system is disconnected

from the power supply!

5 Electrical connection

ATTENTION When attaching accessories with an electrical cable, a minimum

bending radius of 3 x the cable diameter must be maintained for

laying the cable.

Pipe connection

Pipe connection

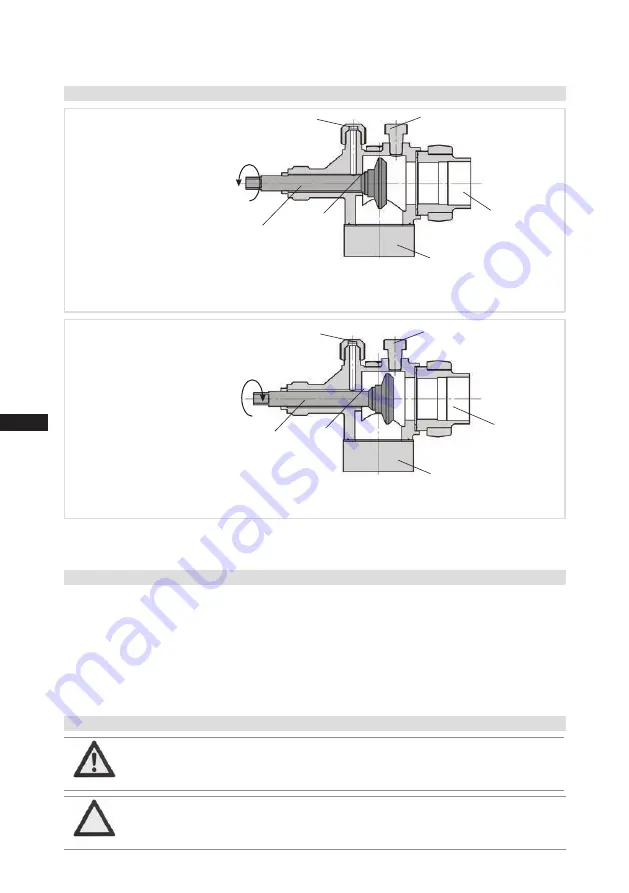

4.8 Operating mode of the lockable service connections

Fig. 16

Opening the shut-off valve:

Spindle: turn to the left (counter-clockwise) as far as it will go.

—> Shut-off valve completely opened / service connection closed.

The connection which cannot be shut off is intended for safety devices.

Fig. 17

Opening the service connection

Spindle: Turn

1

/

2

- 1 turn to the right clockwise.

—> Service connection opened / shut-off valve opened.

The connection which cannot be shut off is intended for safety devices.

Service connection

closed

Connection

blocked

Spindle

Connection cannot

be shut off

Connection cannot

be shut off

Service connection

opened

Spindle

Connection

open

Compressor

Compressor

After activating the spindle, generally fit the spindle protection cap again and tighten with 14 - 16 Nm.

This serves as a second sealing feature during operation.

5| Electrical connection

For systems with long pipes and higher degree of contamination, a filter on the suction-side is

recommended. The filter has to be be renewed depending on the degree of contamination (reduced

pressure loss).

4.9 Suction pipe filter