Modifications reserved

Page 39/49

OPM_SGS_ISG_M75_M75_2US_V010.doc

Installation Guide

SG Series 750 UL S2

&

SG Series 750 T12 UL S2

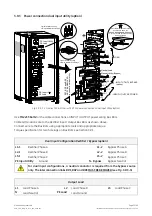

3.10 RPA PARALLEL SYSTEM CONNECTION

WARNING !

This operation must be performed by QUALIFIED SERVICE PERSONNEL ONLY before

the initial start-up.

ENSURE THAT THE UPS INSTALLATION IS COMPLETELY POWERED DOWN.

3.10.1 Power wiring of parallel units

To guarantee good

Load

sharing between the units of a

Parallel System

, we recommend that the cable

length from the input distribution board (5) to the output distribution board (9) is equal for each unit (a+b

= c+d = e+f = g+h = i+l = m+n). Tolerance:

+/- 10%

.

The

RPA Cable Saver

option introduces a bypass inductor in every UPS module, minimizing the influence

of external conductor length on bypass current sharing.

The

RPA Cable Saver

option extends the cable length tolerance to

+/-50%

for runs not exceeding

160

feet

(49m).

The AC input power of the

Bypass

must be the same for all units of the parallel system - no phase shift

allowed between units.

NOTE !

It is strongly recommended that no transformers, automatic circuit breakers or

fuses be inserted between the unit’s output and the

Load

common bus bars.

However, it is recommended that a disconnection or isolation switch be installed in

order to totally isolate a unit if needed.

Verify that power wiring and control wiring are run in separate conduits or cable trays.

UPS input cables must be run in separate conduits from the output cables.

1

= Rectifier

2

= Inverter

3

= Automatic Bypass

4

= Q1 Output UPS switch

5

= Input Utility Distribution

6

= Unit Output Load

7

= External Battery fuse or MCB

8

= External Battery

9

=

Common bus bar and Output

Load Distribution

c

= UPS Number 1

2

= UPS Number 2

3

= UPS Number 3

4

= UPS Number 4

5

= UPS Number 5

Fig. 3.10.1-1 Power wiring of RPA Parallel System

6

= UPS Number 6