8 | GE Oil & Gas

© 2016 General Electric Company. All rights reserved.

4.3 Installation

4.3.1 Positioning

All 173-50 regulators must be installed with the actuator facing

upwards and the diaphragm horizontal.

4.3.2

Installation Diagrams

In most cases the flow crosses the regulator as shown by the

arrow in Figures 9 and 10.

The installation diagrams are therefore as follows:

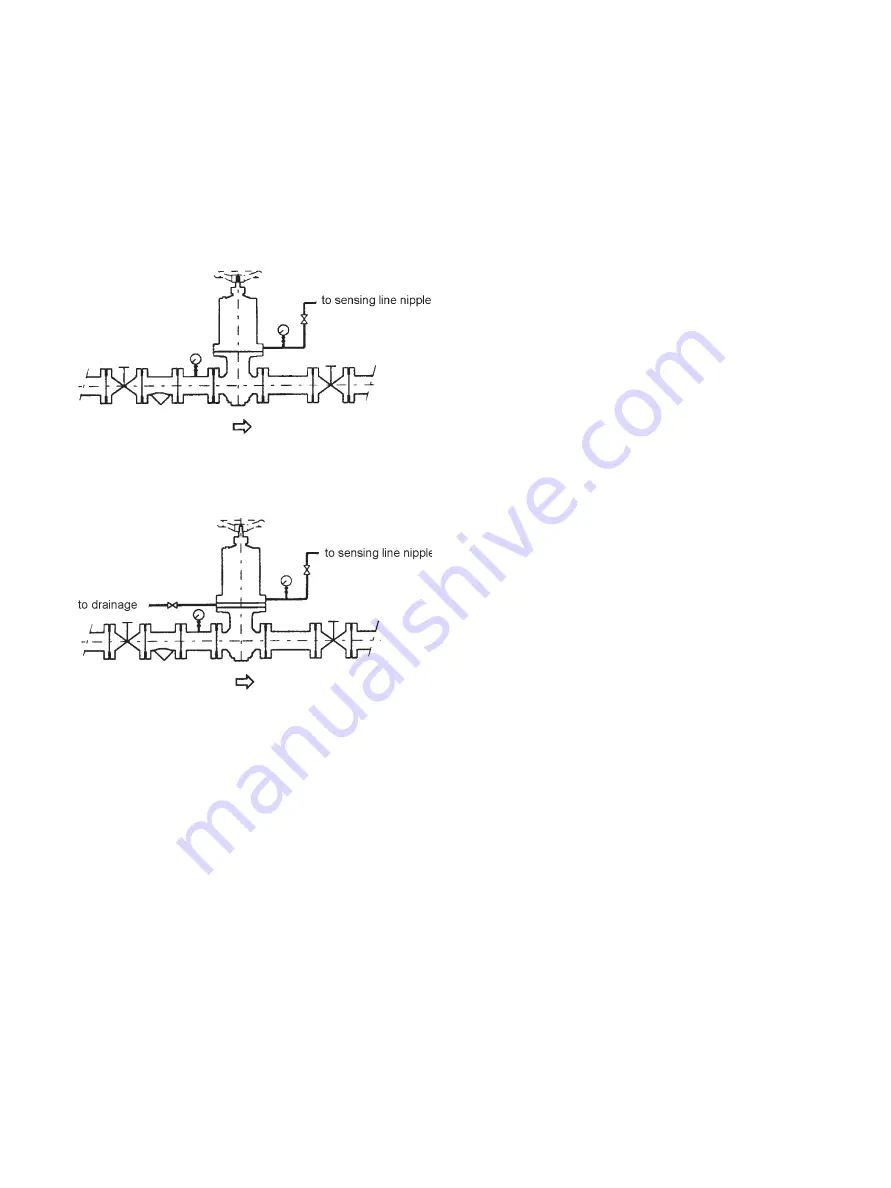

Figure 11

Example of installation layout for 173-50 single diaphragm

regulators

Figure 12

Example of installation layout for 173-50 double diaphragm

regulators

4.3.3 Isolation Valves and Filter/Pressure Gauges

Install an isolation valve upstream, downstream and on the

sensing and discharge line connection piping, in order to service

the regulator (if necessary) while the plant is pressurized.

Install one filter or pressure gauge upstream from the regulator

and another one on the sensing line connection (as shown in

Figures 11 and 12) in order to calibrate the differential pressure

and keep it constantly under control.

4.3.4 Contamination

Prior to installing the regulator in the piping, make sure the inside

of the pipes are clean and free of any debris (machining cuttings,

weld slag, etc.), especially the upstream section; blow down the

piping if possible to eliminate any remaining dirt: small drops of

weld slag may seriously damage the regulator.

4.3.5 Double Diaphragm Discharge Venting

In double diaphragm regulators, the chamber between the two

diaphragms must be connected to piping to vent the discharge

to a suitable place, safely and constantly at atmospheric

pressure. This hole can be closed with a plug or pressure gauge

with an electrical contact for the remote signaling that the

diaphragm has broken, as long as the downstream plant is

protected (as shown in Figure 12).

4.3.6 Safety Relief

If there is any chance that an overflow regulator failure could

cause the pressure upstream from the reduction regulator to

exceed the maximum admissible pressure for the installation,

a safety relief valve must be installed upstream – without an

isolation valve in between – in order to discharge the entire flow

crossing the differential pressure regulator.

4.3.7 Pressure Drops

Because the regulated pressure sensing port is located inside

the regulator, the pressure drops in the inter-connecting piping

between the regulator and the point of use will affect the

accuracy of the maintained set pressure. This pressure drop

must be considered when calculating the size of the connection.

4.3.8 Pressure Variation

When it is essential to avoid pressure variations at the point

of use, the regulators are fitted with an external sensing line

connection that replaces the internal connection and is fitted

to the lower flange of the actuator. This connection must be

connected as near as possible to the point of use where the

installation of a pressure gauge is also recommended.

4.4 Startup and Calibration

(Refer to Figures 9 and 10)

4.4.1 Pressure Difference

This operation is similar for both single diaphragm and double

diaphragm regulators. The sensing line connection regulator and

the upstream and downstream isolation valves must be closed.

Slightly open the downstream valve and then the upstream

valve together with the sensing line connection, making sure

that the pressure difference read on the pressure gauges is

correct. If necessary, to reduce the pressure difference, turn the

adjustment screw (18) clockwise to increase differential pressure

and counterclockwise to decrease.

4.1.2 Calibration

When the required value is reached, fully open all the valves.

When the downstream system is working at full power, calibrate

by adjusting the screw (18).

4.5 Maintenance

(Refer to Figures 9 and 10)

4.5.1 Maintenance Interval

The required maintenance interval will vary depending on

application. The user must establish a suitable maintenance

schedule depending on the operating conditions. Prior to

disassembly, remove all system pressure from the regulator.

Before starting the above operation, make sure the recommended

spare parts are available (See the parts listed in Figures 9 and 10).