GEK-49849

the c l utch pressure and, consequent l y, the current val ue whi ch wi l l cause the c l utch

to s

1

i p .

Note that too frequent or too

1

ong app

1

i cat i on of these currents wi

1 1

overhe at the coi l s .

I NSTANTANEOUS OVERCURRENT UNIT

The sect i on BEAR I NGS, under DI RECT I ONAL UNIT, a l so app l i es to the be ar i ngs of

the i nstantaneous overcurrent u n i t .

and Stator

The sect i on CUP AND STATOR, under D I RECT I ONAL UNIT, a l so appl i es to the cup and

stator of the i nstantaneous overcurrent u n i t .

Contact Adju stments

The contact gap may be adj usted by l oosen i ng s l i ght l y the screw at the front of

the contact support .

The screw shou l d be o n l y l oose enough to al l ow the cont act

barrel to rot ate i n i ts s l eeve .

The backstop screw fastened wi th a l ocknut shou l d hol d the movi n g contact arm

i n a neutral pos i t i on , i . e . , wi th the arm poi nt i ng d i rect l y forwar d .

Then by

rotat i ng the barrel , advance the stat i onary contact u nt i l i t j us t touches the movi ng

cont act . Next, back it away two and a hal f turns to obta i n approxi matel y

0. 080

i nch

g ap . L ast, t i ghten the screw whi ch secures the barre l .

The movi ng contact may be removed by

1

ooseni ng the screw whi ch secures i t to

the contact arm and s l i di ng i t from u n der the screw he ad .

CLUTCH ADJUSTMENT

The c l utch on the i nstantaneous overcurrent un i t can be adj usted by means of

the screw l ocated on the r i ght-hand s i de of the movi ng cont act arm .

If the l ocknut

i s l oosened and the screw turned i n, the current at whi ch the c l utch wi l l s l i p wi l l

be i ncreased .

P l ace the t ap p l ugs i n the l ower range t aps ( s er i es ) . Ho l d the d i rect i onal

u n i t contacts c l osed .

Adj ust the c l utch so that the current at whi ch the cup j ust

starts to s l i p fal l s wi thi n the l im i t s l i sted i n T abl e

14.

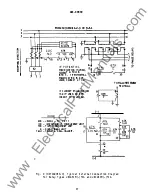

TABL E

14

DI RECT I ONALLY CONTROLLED I OC UNIT CLUTCH ADJUSTMENT

SUDDENLY APPL I ED CURRENT

SUDDENL Y APPL I ED CURRENT

P I CKUP RANGE

CLUTCH MUST NOT SL I P

CLUTCH MUST SL I P

2 - 16

12

15

10 - 80

44

58

Note that too frequent or too l ong of an app l 1 cat 1 on of these currents w1 l l

overheat the coi l s .

2 7

www

. ElectricalPartManuals

. com