*(.&

DIAC / DIFC / DSFC Digital Overcurrent Protection

33

ACCEPTANCE TESTS

Immediately upon receipt of the relay, an

inspection and acceptance test should be made

to make sure that no damage has been

sustained in shipment, and that the relay

calibrations have not been disturbed.

Visual Inspection

Check the nameplate stamping to make sure

that the model number and rating of the relay

agree with the requisition. Remove the relay

from its case and check that there are no broken

or cracked molded parts or other signs of

physical damage, and that all screws are tight.

Mechanical Inspection

1.

The target and seal-in unit, pull and lift

the TOC lever to test the target, repeat

the test for the IOC target. The Target

flag should remain when the lever is re-

leased. Reset the target by pushing the

reset bar.

2.

Make sure that the fingers and shorting

bars agree with the internal connections

diagram.

CAUTION: Every circuit in the drawout case

has an auxiliary brush. It is especially impor-

tant on current circuits and other circuits

with shorting bars that auxiliary brush be

bent high enough to engage the connection

plug or test plug before the main brushes do.

This will prevent CT (current Transformer)

secondary circuits from being opened.

Electrical Tests

DRAWOUT RELAYS, GENERAL

Since all drawout relays in service operate in

their cases, it is recommended that they be

tested in their cases or an equivalent case. A

relay may be tested without removing it from the

panel by using the appropriate test plug. For a C

case, use the XCA test plug; for a V or S case,

use the XLA series test plug (refer to the GE

Power Management Product Catalog). Although

the test plugs provide greater flexibility, it re-

quires C.T. shorting jumpers and exercise of

greater care since connections are made to both

the relay and the external circuitry.

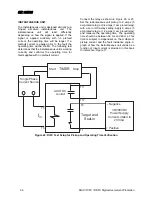

INVERSE TIME UNIT

Pickup Verification

•

Connect the relay as indicated in Figure 24

or 25. In order to apply current to the relay,

use a 50/60 Hz voltage source, with a vari-

able resistor in series, or an electronic cur-

rent source.

•

Set the relay at the desired pickup TOC and

disable the instantaneous unit by setting the

instantaneous current setting to zero (0).

Apply current to the relay and verify that the

Pickup LED on the front of the relay lights be-

tween 98% and 102% of the pickup TOC setting.

If the relay is set to blink between power up and

pickup, look for the LED to be on most or all of

the time to indicate pickup.

Reduce the current applied, verifying that at a

value between 95% and 100% of the pickup

TOC, the relay Pickup LED turns off or blinks if

set to blink.

Verification of Operating Time

Because the Digital self powered series of relays

has many different curve characteristics, the

basic test instruction will be given and the data

for each of the curves can be found in Table 1.

With the relay still connected as indicated in

Figure 24 or 25, set the time overcurrent unit to

minimum pickup and set the corresponding time

dial to 5. Successively apply currents of 2, 5, and

10 times pickup TOC, verifying that the operating

times are within the margins indicated in Table 1.

NOTE: Before attempting to reset the trip

target, ensure the DC supply is removed or

turned off from the trip circuit setup