Pg 4

Insert Filament In Extruder

Plug In and Turn On

3. Pinch the extruder arm above the spring and insert

fi

lament in the white PTFE tube.

4. Slide

fi

lament in un l you see it enter the top of the

tube just under the metal drive gear. The

fi

lament

should slide in about

4 inches more

.

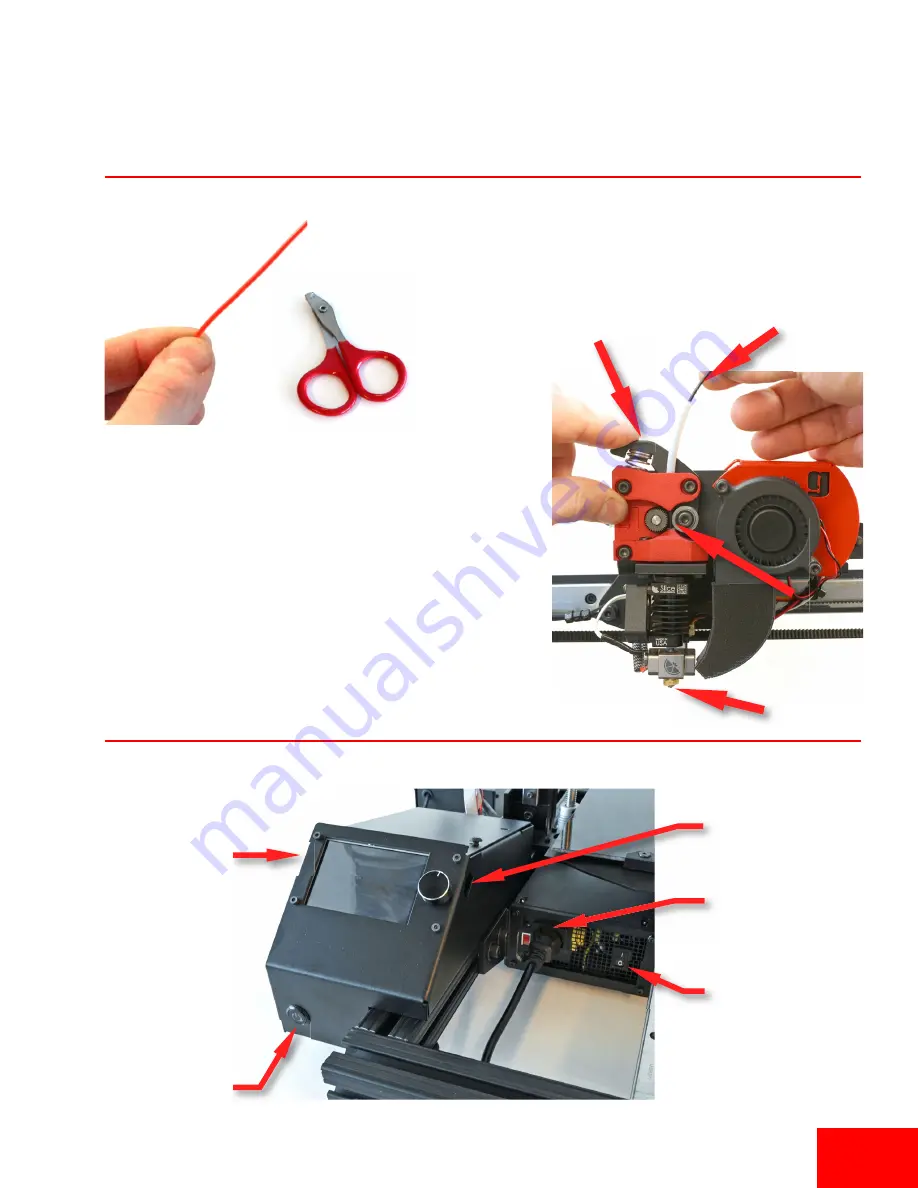

1. Plug in the printer to

a surge protected

power strip.

2. Make sure power

switch is on.

SD Card Slot

Power Bu on

1

USB Slot (use

90 degree adapter)

1. We recommend cu ng o

ff

the

fi

rst 12” of a new spool of

fi

lament.

2. Every me you insert

fi

lament, cut end of

fi

lament at a 45 degree

angle and straighten 4” of the end of the

fi

lament by bending it.