© 2004 General Binding Corporation

Spartan Operation and Maintenance Manual

Page 4-1

4.0 Installation

GBC Films Group is committed to a program of ongoing

product improvement. As a result, we are providing these

instructions so that you can insure that your new Spartan

Laminator is properly and securely unpacked, moved and

installed.

Before a Spartan Laminator can be installed, there are a

few requirements that must be met. Make certain that

each of the requirements listed in the following pre-

installation checklist are met before beginning installation.

CAUTION: Failure to follow the pre-installation

check list can result in damage to the laminator.

4.1 Pre-installation

Are the doorways and hallways wide enough for

the laminator to be moved to the installation site?

Is there ample room for the laminator?

A work area must be established that allows for

unrestricted movement around the laminator and

provides space for efficient material flow. Figure

4.1.4 and Figure 4.1.5 illustrates a typical machine

area layout.

Is the environment appropriate for the laminator?

The laminator requires a clean, dust and vapor

free environment to operate properly. It must not

be located where there is air blowing directly on

the machine.

Have you contacted a certified electrician to install

a receptacle for the laminator ensuring that

adequate power is being supplied and correct

circuit breaker?

WARNING: The operating environment must be

free of dust, flammable liquids and vapors. You can

be injured by inhaling chemical vapors.

WARNING: Vapor build up or stored flammable

liquids can cause a fire. Excessive dust can damage

the laminator.

CAUTION: Do not locate the laminator where air

can blow directly on the machine. The air flow can

cool the rollers unevenly and result in poor quality

output.

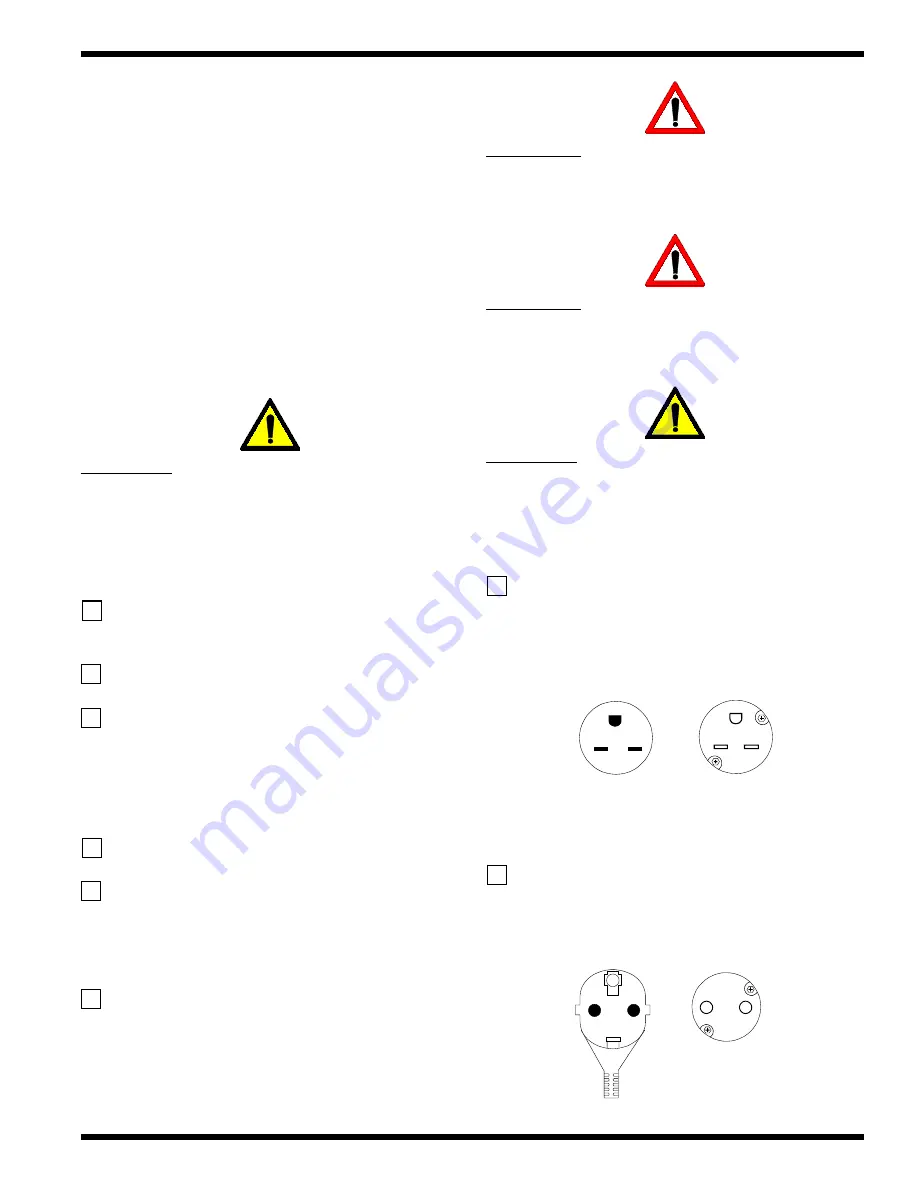

US and Canada: The laminator requires 230-

240 vac, 60 Hz, 15 amps, single phase

Figure 4.1.1 Connections-Spartan US

N E M A 6 - 1 5 R

N E M A 6 - 1 5 P

Europe: The laminator requires 230-240, 50 Hz

16 amps, single phase

Figure 4.1.2 Connections-Spartan Europe

1 6 re c e p ta c le

1 6 p lu g

Содержание 930-073

Страница 4: ...2004 General Binding Corporation Spartan Operation and Maintenance Manual Page II...

Страница 8: ...2004 General Binding Corporation Spartan Operation and Maintenance Manual Page 1 4...

Страница 25: ......

Страница 26: ...General Binding Corporation One GBC Plaza Northbrook IL 60062 4195...