3

2

、

Installation Guideline

★

Installation should be followed below requirements

:

The walls on top of the working face and next to the installation of induction cooker

must be heat-proof.

The laminated boards and adhesive used for installation must be heat-resistant.

For any installation method, the air under the cooker and behind the cooking range

should have enough space for cooling in order to ensure the safety of operating the

induction cooker.

Based on the prescribed dimensions, a square hole is opened on the work table. Ensure

the distance between any side of the work table and the walls is

100mm.

Protect the opening: If in contact with damp, the laminated boards used in marking the

work table will easily expand more. It is required to stick varnish or special adhesive onto

the edge of the opening in order to prevent any steam from condensation under the

work table.

For any condition of installation, the induction cooker should have a good ventilation

condition with air inlet and air outlet not blocked.

Don’t place other equipments on the working face of the double cooking zones of the

induction cooker and within the range of 30cm around the working face.

If choosing a table-top installation, ventilation hole shall be at least 100mm from wall

surface.

The induction cooker must be complied with a 13A power outlet.

★

Steps on Installation

:

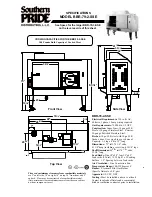

~ Open an installation hole on the worktop of cabinet as per

illustration 1

.

(Note : The height shall be more than 100mm)

Cut out dimensions(unit/mm)

(W) 670 x (D) 350 x (H) 100

illustration 1

* If the installation hole on the work table is a new open, it is recommended a depth to

370mm and put the cooker into the hole at front side so at to have a good ventilation

condition.