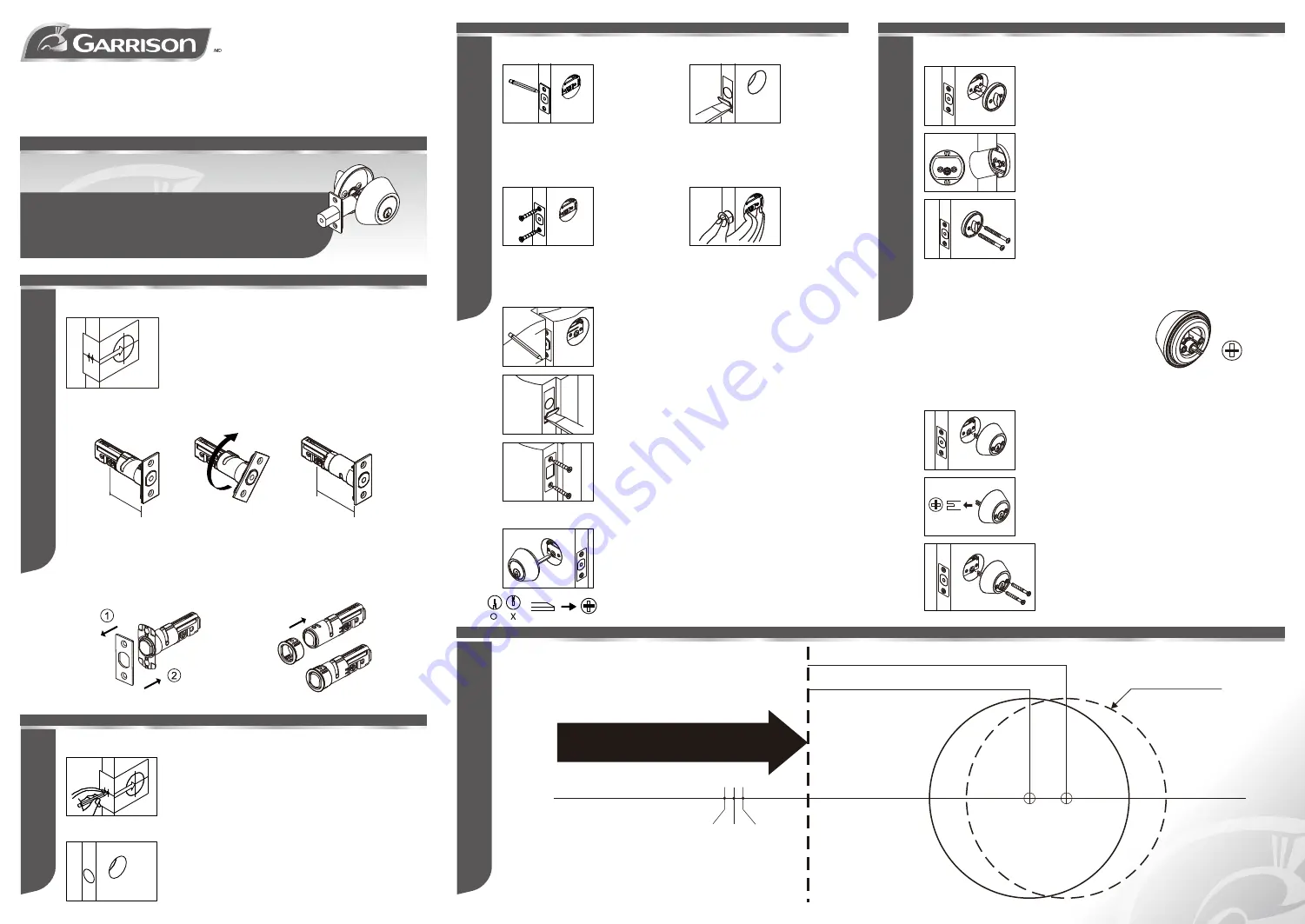

For use on doors 1 3/8" to 1 3/4" (35 mm-45 mm) thick

Adjustable latch for 2 3/8" (60 mm) and 2 3/4" (70 mm) backset

Backset is a distance from door edge to centr of hole on

door face.

Some locks are supplied with adjustable latch which can fit

2 3/8" (60 mm) or 2 3/4" (70 mm) backset.

Follow the steps shown below to change backset.

e

Rotate

illustrated below,

Latch backset adjustment

the latch case as

for backset 2 3/4" (70 mm) or reverse

direction for 2 3/8" (60 mm).

Template

®

45

40

35

Mark 1" (25.4mm) hole at center of door edge.

For 2 3/8" (60 mm) backset

For 2 3/4" (70 mm) backset

ø

(

)

2 1/8" 54 mm

Fold on dotted line and fit on door edge

1 3/4"

1 3/8"

1 9/16"

INSTRUCTIONS FOR INSTALLATION

OF DEADBOLT LOCK

Installation

Installation

IMPORTANT

: Please read this manual carefully

before installing this deadbolt lock and save it for reference.

Toll-free

Number: 1-800-268-6591

model no.: 046-5631-0 & 046-5688-6 & 046-5690-8

180°

2 3/4" (70 mm)

2 3/8" (60 mm)

70 mm

60 mm

To change latch face

the faceplate from backplate.

2. Snap the selected faceplate onto backplate.

1. Use a flat-head screwdriver to separate

Drive in installation

Make sure the round faceplate is

properly aligned as illustrated and

snap it to the latch case.

Installation

Drive-in latch

1. Mark the door with template

Select 2 3/8" or 2 3/4" (60 mm or 70 mm) backset

as desired and mark centre of hole on door face.

c. Insert latch and tighten screw.

d.

For drive in latch, drill 1" (25.4 mm)

hole and press latch until it is flush

with door edge.

3. Install latch

a. Insert latch in hole and keep it parallel

to door face.

Mark outline of face plate and remove

latch.

b. Chisel 5/32" (4 mm) deep inside

traced outline or until face plate

is flush with door edge.

a

c

b

d

a

b

c

4. Install strike

c.

Install strike and

tighten screws.

a. Close the door so the latchbolt is against the door frame.

b. Measure one half of door thickness from door stop

and vertically mark center line of strike. Drill 1"

(25.4 mm) hole, 1" (25.4 mm) deep at intersection of

horizontal and vertical line of strike. Mark outline

using strike plate and chisel 5/64" (2 mm) deep for

strike.

5. Install single cylinder exterior mechanism

Press cylinder side flush against door making certain the

tailpiece is properly positioned in latch crank. Tapped

holes in housing of exterior cylinder should be lined up

with screw holes. Key hole should be in down position.

TAILPIECE SHOULD BE HORIZONTALLY INSERTED INTO

LATCH CRANK.

6. Install single cylinder interior mechanism

a. Slide turnpiece and interior rosette.

b. Insert both flanges into the hole on the door face.

Make sure the flanges stay in the hole when fastening

screws.

c. Insert machine screws through holes in cylinder and

tighten firmly.

8. Install interior cylinder (double cylinder)

Latch adjustment

2. Drill holes

a. Drill 2" (51 mm) hole through door face, from both

sides to avoid wood splitting.

b. Drill 1" (25.4 mm) hole for latch

(refer to step 3d for drive-in latch).

7. Install exterior cylinder (double cylinder)

a. Press interior assembly flush against door, making certain

the tailpiece is properly positioned in latch crank.

Key hole should be in down position.

b. The interior tailpiece

inserted into the exterior

blade.

must be

c. Insert two screws through countersunk holes

in exterior cylinder and tighten firmly.

Press exterior cylinder flush against door.

Exterior tailpiece should be horizontally inserted

into latch crank first.

a

b

c

a

b

c

G

-

LT

-

01