Part # 4020897 (01/31/08)

Page 7

OPERATION

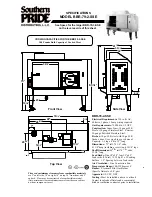

Display

= Is actual value

With use of an external temperature probe / the

variables can be regulated infinitely.

= Actual temperature key with use of the temperature

probe,

=Hold keeping warm facility.

= Cooking level “low, mid and high”, are

preprogrammed, but can be changed individually by /

keys.

= On/Off key.

Function Test

Before carrying out function checks, the operator must know

how to operate the cooker.

Induction Unit

Surface View

Heating Area

Coil

Your cooker must be positioned in a suitable place and

connected to a voltage supply. Make sure the cooker is well

positioned and free from exposure to vibration.

Make sure the unit is in the “OFF” position.

Remove all objects from the glass ceramic cooking zone,

verify if this area is neither cracked not broken. Don’t

continue with use when the glass ceramic cooking zone is

cracked or broken, immediately switch off and disconnect

the cooker from the outlet.

CAUTION The glass ceramic cooking zone is warmed up

from the heat of the pan. To avoid injuries (burning) do not

touch this area.

Use a pan that is suitable for induction cooking, having a

bottom diameter of at least 127 mm (5 inches).

1. Put some water in the pan and place the pan in the center

of the heating area.

2. Push “ON” as well as a position between 1 and 12. The

indicator will illuminate lights (red) and the water will be

heated.

3. Take the pan away from the heating area, the indicator

light will flash.

4. Place the pan back on the heating area, the indicator light

will illuminate and the heating process will continue.

5. Push “OFF”, the heating process will stop, indicator light

turns off.

The shining indicator light operation means that energy is

being transferred to the pan.

If the indicator operation remains off, check the following:

1. Is the cooker connected to the outlet?

2. Are the indicator lights “ON”?

3. Did you use a suitable pan (bottom diameter at least

127mm (5 inches), pan made of suitable material)?

4. Is the pan placed in the center of the heating area?

To verify if the pan is suitable, use a permanent magnet and

find out if it sticks to the bottom of the pan. If not, your pan

is not suitable for induction cooking. Choose a pan which is

recommended for induction cooking.

If in spite of all positive controls and tests the cooker doesn’t

work, refer to the Trouble Shooting Section.

Содержание GMIU3.5

Страница 2: ...Part 4520897 01 31 08 Page...

Страница 14: ...Part 4520897 01 31 08 Page 14...

Страница 15: ...Part 4020897 01 31 08 Page 15...

Страница 16: ......