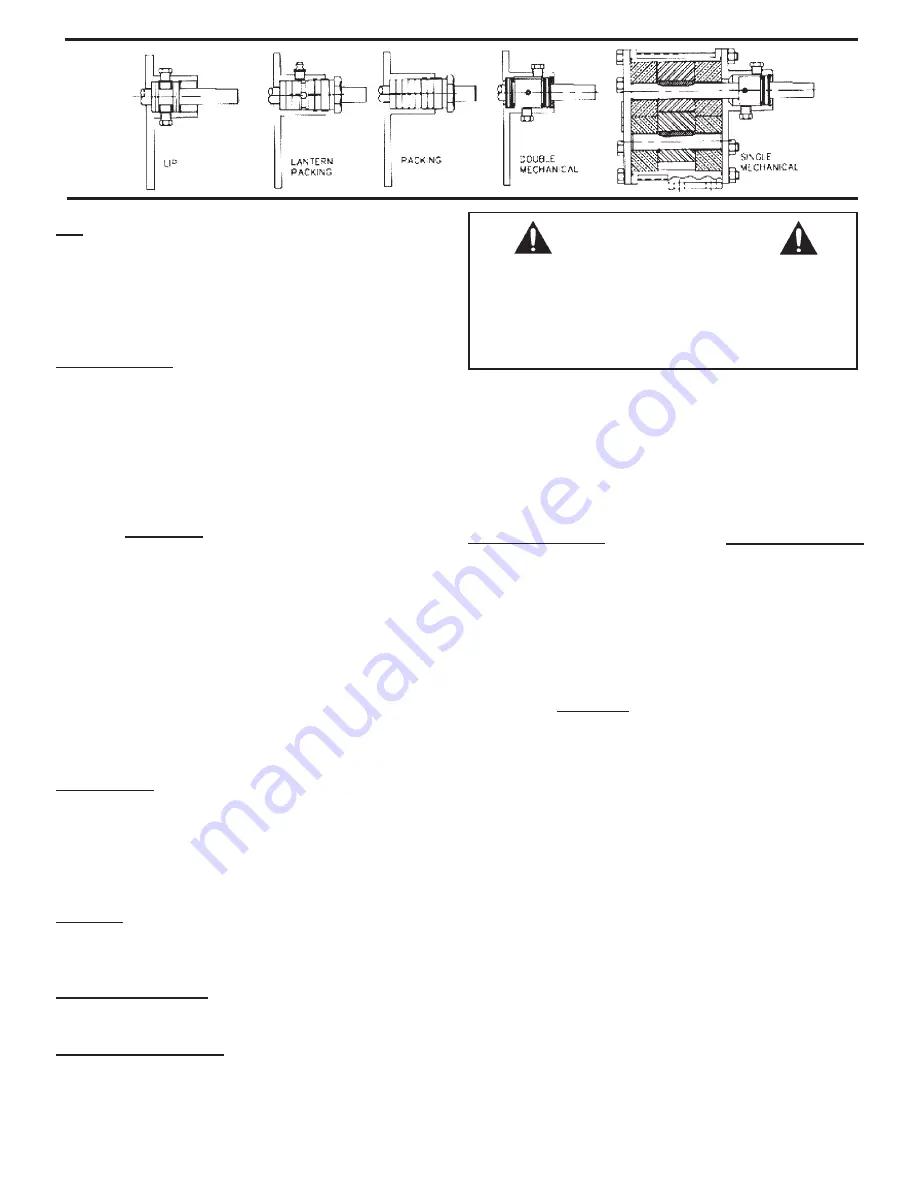

Lip:

Pumps supplied with two lip seals and flush chamber

arrangement come factory supplied with a small amount of lubri-

cant applied to the outer lip seal. The design is intended to be used

with an eternally supplied flush fluid. Remove the pipe plugs and

install "in" and "out" connections to the flush source. Failure to

supply flush fluid will lead to outer lip seal breakdown.

Mechanical Seals:

(see above)

Two types are offered as standard:

single internal (in both the wedge and bellows styles) and double

mechanical seals (in both the wedge and bellows styles). Both

require cooling and lubrication to perform properly. Do not run

pump dry. Ensure that the seal surfaces are wet prior to start-up

and operation. If a seal flush system is to be used, make sure the

system is connected to the cover ports correctly. Keep abrasives

out of the seal area. Dirty flush streams can destroy seal faces.

Operation

Pre-Startup

Prior to start-up, recheck installation as described above. Verify

desired rotation by jogging the motor and make corrections if nec-

essary. Before initial startup, pre-wet the gears and seal, make

sure the pump is adequately primed. Failure to do so could cause

immediate damage to pump components. Make sure that dis-

charge valves are open.

Startup

Start pump and check for proper operation.

Packing Styles:

Adjust packing as necessary, allowing adequate

time to run in. Do not overtighten the packing nut else damage to

the packing and the shaft can occur. A properly packed and adjust-

ed packing nut will leak at about 10 drops every 3 to 5 minutes.

A packing nut runs hot, it is generally a sign that the packing is

too tight.

Lip Styles:

No adjustment is necessary during operation. For two

lip arrangements, insure that flush fluid continues to be

supplied

to the

chamber.

Single Mechanical Seals

: No seal adjustment is necessary. Check

mechanical seal flush arrangements where used.

Double Mechanical Seals:

Pressurized flush must be in opera-

tion at an inlet pressure of 10 to 15 psi above intended pump dis-

charge pressure prior to and when operating the pump. Flush must

continue when pump is stopped until pump pressure is reduced to

within 20 psi of double seal chamber pressure.

If the pump's bearing areas or seal area runs hot, shut the pump

down and determine the cause. It is recommended that the line

mounted pressure relief setting should be 5 psig above the oper-

ating pressure in the discharge line. If start-up screens were used,

be sure they are removed prior to placing the system into regular

operation. Depending on suction conditions, it may be necessary

to reprime the pump for subsequent restarts.

Maintenance

Frequency

Since each installation differs, the frequency and extent of pump

maintenance is best established based upon past performance.

Keeping detailed maintenance records of past performance aids in

determining future preventative maintenance intervals. During

routine operating inspections, pay particular attention to seal and

bearing areas of the pump. Consult the motor manufacturer for

motor maintenance instructions.

Changing Applications

Verify that all wetted parts of the pump are compatible with the

new fluid to be handled and that the motor is adequately sized.

Check with your Oberdorfer distributor if in doubt.

Inspect for Wear

If your Chemsteel® Gear Pump exhibits reduced flow, an inabil-

ity to maintain pressure, is noisy or performs otherwise abnor-

mally, first refer to the Troubleshooting Matrix below. If the prob-

lem persists, the pump should be inspected for wear or damage.

Oberdorfer Chemsteel® Gear pump internals may be readily

inspected in the field usually without removal from the drive or

Dry running leads to immediate damage to pump components.

Due to tight running clearances, liquids containing

solids and abrasives will accelerate pump wear.

When possible, flush the pump after each usage.

Allowing liquid to freeze in the pump can cause damage.

WARNING

Before attempting to service the pump: Disconnect motor power

and release all pressure within the system. Flush the pump thor-

oughly with a neutralizing fluid before attempting to disassemble.

Wear appropriate personal protection equipment and handle the

equipment with care.

CAUTION

3