18

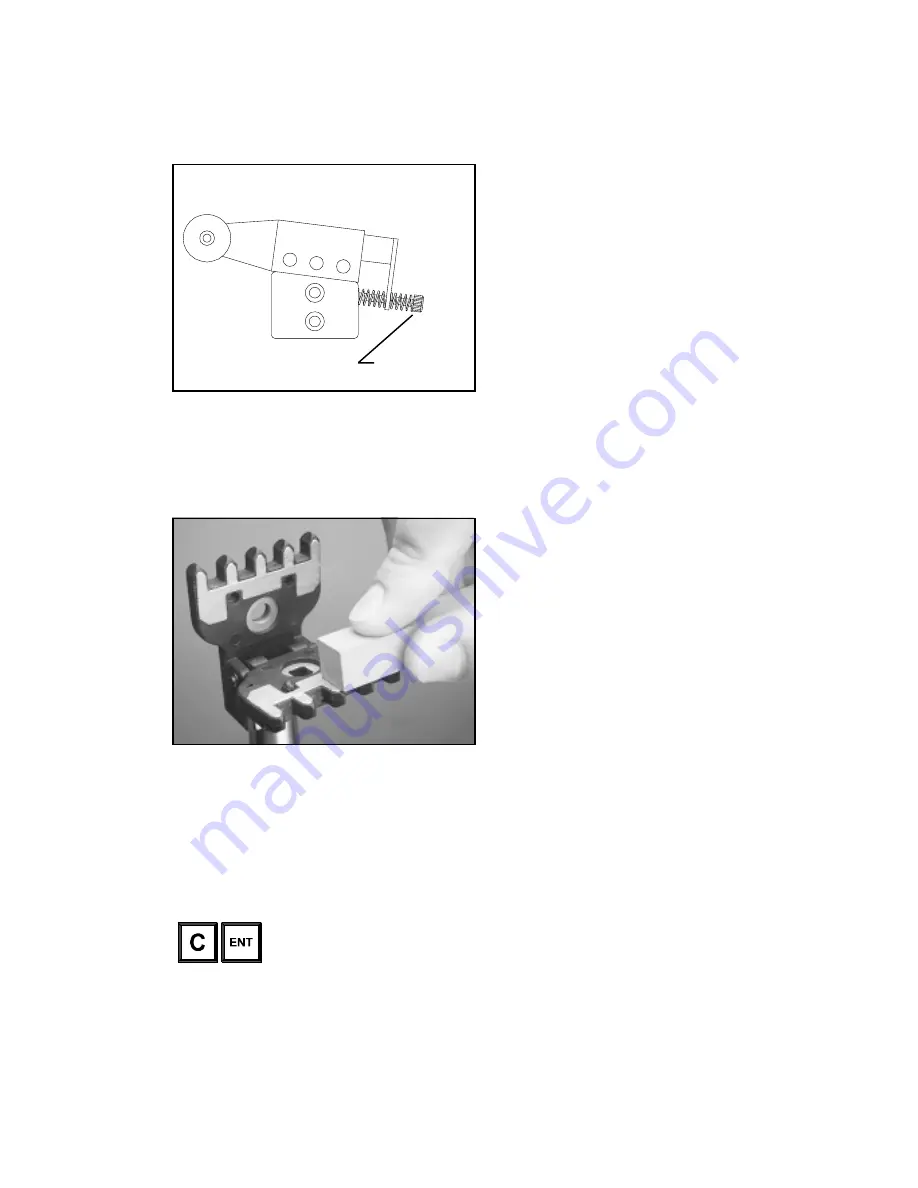

Setting the Gripper Plate Spacing

The parallel plates of the string gripper are adjustable to

accomodate varying string gauges and types of string. If

the string slips through the gripper plates while pulling

tension, rotate the gripper adjustment screw counter-

clockwise. If the string is damaged while pulling tension,

rotate the gripper adjustment screw clockwise. The

gripper is properly adjusted when there is enough pres-

sure to securely grip the string without causing damage

to the string.

Gripper Adjustment

Screw

Buzzer Control

The stringing machine is equipped with a buzzer function that sounds when any key or button is pressed; it also sounds

an intermittent warning when the tensioner has pulled a string to the end of its travel and is not yet at tension, or if there

is an internal error in the machine. The buzzer can, however, be disabled for normal key / button presses. To toggle

between buzzer enabled / buzzer disabled modes:

Turn the machine on; while the display is counting down from 9 to 0, press the clear (C) and enter

(ENT) keys together. The machine will switch modes, and the changes will remain in effect until

the user toggles modes again.

NOTE:

In disabled mode, the buzzer will still sound if the tensioner has pulled a string to the end of its travel and is

not yet at tension, or if there is an internal error in the machine. This is meant to alert the user of a problem, and should

never be disabled.

Cleaning Instructions for String Clamps

To thoroughly clean the diamond coated surfaces of the

clamp heads, remove the adjustment knob screw, lever

plate, and compression spring to expose the inside

surfaces of the clamps. Using the cleaning stone pro-

vided with your machine (you can also use a small tooth

brush or a sharpening stone for knives), scrub the

diamond coated plates until all debris is removed. Clean

any dust or residue with a damp cloth and re-assemble

the clamp head.