SMART PRO 5.0 Pág. 26

Working Principle

Working Principle

Working Principle

Working Principle

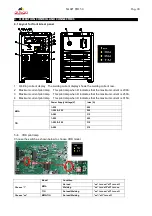

The working principle of SMART PRO 5.0 (PFC)welder is shown as the following figure. Single phase

208V

-

460V±10%work frequency (50/60 Hz) AC is rectified into DC, three phase 208V

-

460V±10%work

frequency (50/60 Hz) AC is rectified into DC, then by PFC circuit, DC(about 750V)is converted to medium

frequency AC (about 20KHz) by inverter device (IGBT module), after reducing voltage by medium transformer

(the main transformer) and rectified by medium frequency rectifier (fast recovery diodes), and is outputted by

inductance filtering. The circuit adopts current feedback control technology to insure current output stably.

Meanwhile, the welding current parameter can be adjusted continuously and steplessly to meet with the

requirements of welding craft.

PFC

Inverter

Medium

frequency

transformer

Medium

frequency

rectify

Hall device

Current positive-

feedback control

Single-phase AC

DC

AC

DC

AC

DC

Rectify

208-460V 50/60Hz

208-460V 50/60Hz

Three-phase AC

Volt

Volt

Volt

Volt----Ampere Characteristic

Ampere Characteristic

Ampere Characteristic

Ampere Characteristic

SMART PRO 5.0 welders have excellent volt-ampere characteristic, seeing the following graph. In MMA

welding, the relation between the rated loading voltage U

2

and welding current I

2

is as follows:

When I

2

≤600A

,

U

2

=

20

+

0.04 I

2

(

V

) ;

When I

2

>

600A

,

U

2

=

44

(

V

)

.

64

44

20

0

600

I

2

(

A

)

U

2

(

V

)

Working

point

Volt-ampere characteristic

The relation of the rated loading

voltage&welding current

....