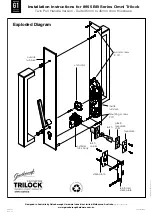

Step 7

• Install 2 posts to Trilock external faceplate

(this is the faceplate

without

the r

ectangular snib

push-button).

Step 8

• Mount the Inside face plate so that

mark on large gear engages with mark

on lock bodygear

NOTE:

•

carefully follow these instructions when installing.

•

do not overtighten screws.

•

use of power driver is not recommended.

•

fully remove the Trilock prior to painting the door

to avoid harming the product's finish.

Step 5

• Remove perforated cut-out from

card-board template and place over

lock body, making sure template is

square to door edge.

• While holding template firmly in

position, mark remaining 3 holes, as

indicated on both sides of the door

(r

eversing template as required).

• Drill pilot holes from both sides of the

door [suggested size 3mm (1/8")] then

enlarge, again from both sides of the

door, to sizes indicated on template,

otherwise correct functioning may be

impeded – refer template.

Step 6

To rehand external lever & set

lever operation (if required).

• If rehanding is required remove the stop

screw from SS1 & fit to SS2, to allow Lever

to operate away from door edge

NOTE:

There is no need to rehand the internal lever.

NOTE:

These steps are applicable to leverset only.

Step 9

• Insert spring and snib rotor in the square hole

of the internal lever

.

• Position snib rotor so one notch faces up and

the other notch points to the latch side.

• Mount outside furniture plate to outside of the

door, and align the two making sure the snib

rotor engages with the external lever

.

• Fit mounting screws from inside and tighten

into threaded posts.

• Fit wood screws 3 off to inside furniture plate

(recommend pilot drilling before fitting screws).

NOTE:

T

est all functions for smooth operation.

SS2

SS1

1

3

2

Note:

Position Snib Rotor so one notch faces

up & the other notch points to the door edge.

Mounting screws (2 off)

Wood screws (3 off)

Installation Instructions for 8955 BB Series Omni Trilock

Twin Pull Handle Version - Suits 35mm to 45mm door thickness