Contents

Tests and approvals ......................... 2

Explanation of symbols / foreword ... 3

Body

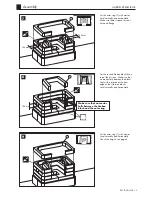

Preparations ................................... 4

Important measurements................... 5

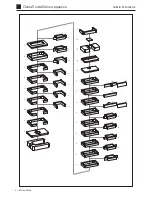

Overall installation sequence ............ 6

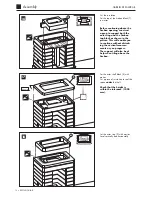

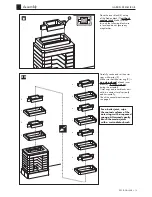

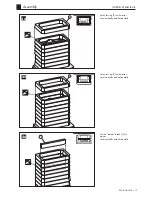

Assembly ...................................7-18

Radiation plate installation ............. 19

Tiles and cassette

Tiling - preparations ....................... 20

Tiling - recommendations ................ 22

Tiling - assembly............................ 23

Cassette - assembly ....................... 24

Fan installation ............................. 27

TMS 2015-10-16

Assembly instruction

Rectangular tile stoves

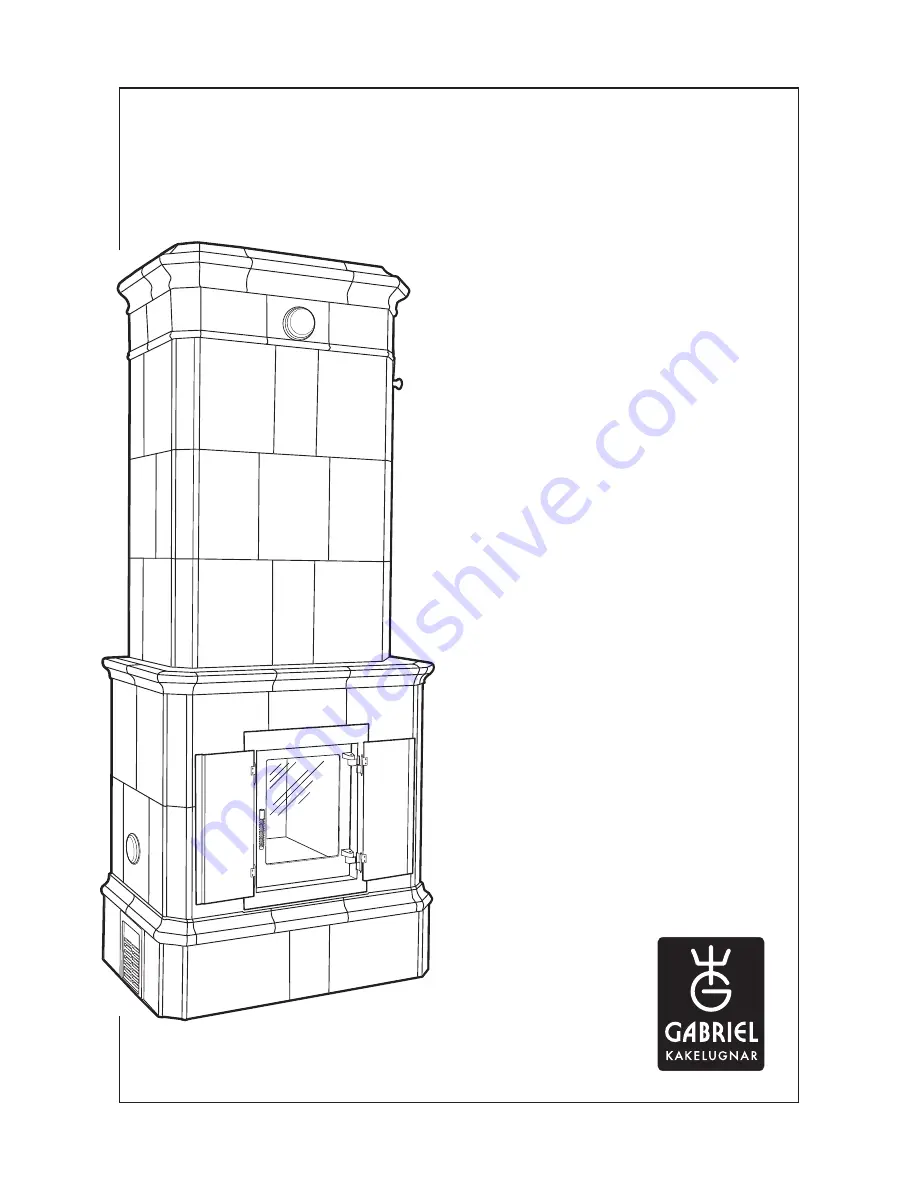

Model:

G820 Strömsrum

G830 Borgholm

G840 Ekeby

G855 Kungälv