10

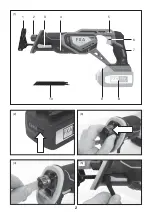

OPERATING THE SAW

GENERAL CUTTING

Hold the saw firmly in front of and clearly away from

you. Make sure saw blade is clear of any foreign

material. Be sure material to be cut is held firmly.

Small work pieces should be securely clamped in a

vice or with clamps to the work bench or table. Mark

the line of cut clearly. Depress the lock-off button,

then pull switch trigger to start the cutting action.

Place the base assembly against the work, then move

the blade into the work. Do not force. Use only

enough pressure to keep the saw cutting. Let the

blade and saw do the work. Use of excessive pressure

that causes bending or twisting of the blade may

result in broken blades.

PLUNGE CUTTING

Mark the line of cut clearly. Choose a convenient

starting point inside the area to be cut out and place

the tip of the blade over that point. Rest the front edge

of shoe assembly on the workpiece and hold firmly in

position. Depress the lock-off button, then pull the

On/Off trigger to start the cutting action.

WARNING: Make sure blade does not touch work until

motor reaches full speed, since this could cause loss

of control resulting in serious injury.

With saw blade at full cutting speed, slowly tilt saw

downward until tip of blade starts cutting work. After

blade penetrates work, tilt saw until blade is

perpendicular to the work.

WARNING:

blades longer than 15cm can whip and

should not be used for plunge cutting. Failure to heed

this warning can result in serious personal injury.

Cutting into electrical wiring can cause the blade, the

blade clamp, and the saw bar assembly to become

electrically live. Do not touch metal parts when cutting

into a wall; grasp only the insulated surfaces on the

tool. Make sure hidden electrical wiring, water pipes,

and mechanical hazards are not in the blade path

when cutting into a wall.

METAL CUTTING

You may cut metals such as sheet steel, pipe, steel

rods, aluminum, brass, and copper with the saw.

Observe the following tips when metal cutting:

Do not to twist or bend the saw blade.

Do not force the tool and use a slow speed setting.

Use cutting oil when cutting soft metals and steel.

Cutting oil also keeps the blades cool, increases

cutting action, and prolongs blade life.

Never use gasoline since normal sparking of motor

could ignite fumes.

Clamp the workpiece firmly and cut close to the

clamping point to eliminate any vibration of the

workpiece. When cutting conduit pipe or angle iron,

clamp the workpiece in a vice if possible and cut

close to the vice. To cut thin sheet material,

“sandwich” the material between hardboard or

plywood and clamp the layers to eliminate vibration

and material tearing.

Always keep firm pressure on the shoe to hold it

securely against the workpiece.

MAINTENANCE

WARNING! Always remove battery pack from your

tool when you are assembling parts, making

adjustments, cleaning, or when not in use. Removing

battery pack will prevent accidental starting that could

cause serious personal injury.

WARNING! When servicing only use identical

replacement parts. Use of any other parts may create

a hazard or cause product damage.

WARNING! Always wear safety goggles or safety

glasses with side shields during power tool operation

or when blowing dust. If operation is dusty, also wear

a dust mask.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts.

Most plastics are susceptible to damage from various

types of commercial solvents and may be damaged

by their use. Use clean cloths to remove dirt, dust, oil,

grease, etc.

WARNING! Do not at any time let brake fluids,

gasoline, petroleum based products, penetrating oils,

etc., come in contact with plastic parts. Chemicals

can damage, weaken or destroy plastic which may

result in serious personal injury.

Tools used on fiberglass material, wallboard,

spackling compounds, or plaster are subject to

accelerated wear and possible premature failure

because the fiberglass chips and grindings are highly

abrasive to bearings, brushes, commutators, etc.

Consequently, we do not recommended using this

tool for extended work on these types of materials.

However, if you do work with any of these materials, it

is extremely important to clean the tool using

compressed air.

LUBRICATION

All of the bearings in this tool are lubricated with a

sufficient amount of high grade lubricant for the life of

the unit under normal operating conditions. Therefore,

no further lubrication is required.

TECHNICAL SPECIFICATION

Voltage

18V DC

No load speed

0-3000min

-1

Stroke length

25.4mm

Max cut in wood

80mm

Max cut in steel

10mm

Sound Pressure Level

L

pA

81 dB(A)

K=3dB(A)

Sound Power Level

L

WA

92 dB(A)

K=3dB(A)

Vibration Level

8.3 m/s

2

, K=1.5m/s

2

Содержание XCLICK FXAJD5218

Страница 2: ...2 1 7 1 5 3 2 9 8 6 10 4 5 3 2 4...

Страница 3: ...3 8 9 7 6...

Страница 37: ...37 2 FXA XCLICK FXADL1051 FXAJDB180Li FXAJDB180Li II...

Страница 38: ...38 ANSI Z87 1 10 25 35...

Страница 39: ...39 30 90 3 5 7 9 30 30 30 45 30 45 5 3...

Страница 40: ...40 1 2 3...

Страница 41: ...41 4 5 a b c d 6...

Страница 42: ...42 1 18 230 50 60 30 1 2 3 4 5 6 7 8 9 10...

Страница 43: ...43 2 10 14 18 3 4 5 6 0 10 10 25 25 50 50 75 75 100...

Страница 44: ...44 7 8 9 15...

Страница 45: ...45 18 0 3000 25 4 80 10 LpA 81 A K 3 A LWA 92 A K 3 A 8 3 2 K 1 5 2 WEEE...

Страница 46: ...46 130 Li ion...

Страница 73: ...73...

Страница 74: ...74...

Страница 75: ...75...