UM9090Rev1

4

6. INSTALLATION

6. INSTALLATION

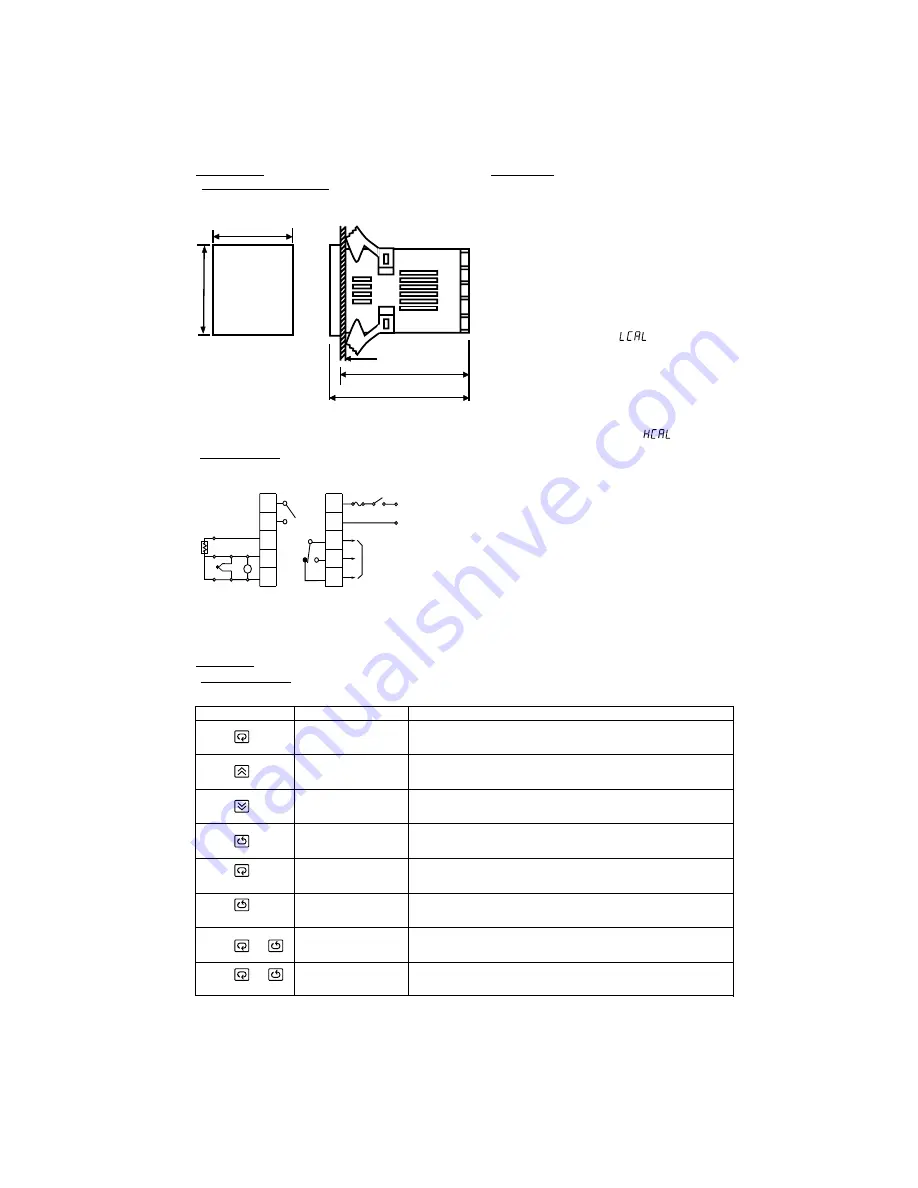

6.1 DIMENSIONS & PANEL CUTOUT

6.1 DIMENSIONS & PANEL CUTOUT

Panel

(45 mm)

Figure 6.1 Mounting Dimensions

TOUCHKEYS

FUNCTION

DESCRIPTION

Scroll Key

Long Scroll

Press

for 6 seconds

Press

and

Up Key

Down Key

Return Key

Long Return

Output Percentage

Monitor

Manual Mode

Execution

* F1: Fuse, S1: Power Switch

6.2 WIRING DIAGRAM

6.2 WIRING DIAGRAM

8. OPERATION

8. OPERATION

8.1 KEYPAD OPERATION

8.1 KEYPAD OPERATION

Press

for 6 seconds

Press

and

for 6 seconds

Increases the parameter

Advance the index display to the desired position.

Index advanced continuously and cyclically by pressing this keypad.

Decreases the parameter

Resets the controller to its normal status. Also stops auto-tuning,

output percentage monitoring and manual mode operation.

Allows more parameters to be inspected or changed.

1. Executes auto-tuning function

2. Calibrates control when in calibration level

Allows the set point display to indicate the control output value.

Allows the controller to enter the manual mode.

7. CALIBRATION

7. CALIBRATION

FDC-9090

1

2

3

4

5

6

7

8

9

10

+

+

+

_

_

_

Alarm

Com.

Alarm

N/O

V

Control Output 1

F1 S1

90 - 264 VAC,50/60HZ

RTD

* With power on, it has to wait for 12 seconds to memorize the new values of parameters once it been changed.

Note: Do not proceed through this section unless their is a

genuine need to re-calibrate the controller. All previous

calibration date will be lost. Do not attempt re-calibration

unless you have available appropriate calibration equipment.

If calibration data is lost, you will need to return the controller

to your supplier who may apply a charge for re-calibration.

Note: Do not proceed through this section unless their is a

genuine need to re-calibrate the controller. All previous

calibration date will be lost. Do not attempt re-calibration

unless you have available appropriate calibration equipment.

If calibration data is lost, you will need to return the controller

to your supplier who may apply a charge for re-calibration.

Prior to calibration ensure that all parameter settings are

correct (input type, C / F, resolution, low range, high range).

B

B

1. Remove sensor input wiring and connect a standard input

simulator of the correct type to the controller input. Verify

correct polarity. Set simulated signal to coincide with low

process signal (e.g. zero degrees).

2. Use the Scroll Key until the "

" appears on the PV

Display. (Refer to 8.2)

3. Use the Up and Down Keys until the SV Display

represents the simulated input.

4. Press the Return Key for at least 6 seconds(maximum 16

seconds), then release. This enters the low calibration

figure into the controller's non-volatile memory.

5. Press and release the Scroll Key. "

" appears on

the PV Display. This indicates the high calibration point.

6. Increase the simulated input signal to coincide with high

11 process signal (e.g. 100 degrees).

7. Use the Up and Down Keys until the SV Display

represents the simulated high input.

8. Press the Return Key for at least 6 seconds (maximum 16

seconds), then release. This enters the high calibration

figure into the controller's non-volatile memory.

9. Turn power off the unit, remove all test wiring and replace

sensor wiring (observing polarity).

1.77 “

1.77

“

(45

m

m

)

94 mm

3.70 “

86 mm

3.38 “