1-7-8

T6550MTI

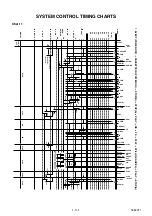

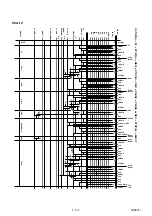

Mechanical Malfunction determination

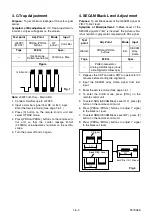

1) REEL Malfunction detection

Countermeasure for REEL and CAPSTAN motor

rotation malfunction (Except CASSETTE LOAD-

ING function)

After the Malfunction detection with REEL/CAP-

STAN sensor, the unit shall switch over to STOP

(B) and be REEL Mechanical Malfunction.

a) If the T-REEL pulse is not impressed after a lapse

of 7 sec. at SP, 14 sec. at LP, or more in the REEL

Rotation Mode like PLAY/REC, FS/RS Mode, and

the T-REEL or S-REEL pulse is not impress after a

lapse of 4 sec. or more in REEL Rotation Mode of

FF/REW, it shall be assumed to stop the rotation

and switch over to STOP (B) position, then

POWER be turned OFF and the unit be REEL

Mechanical Malfunction. (T-REEL and S-REEL for

the models on S-REEL and only T-REEL for other

models)

b) If the C-FG pulse is not impressed for a lapse of 1

sec. or more during the CAPSTAN MOTOR rota-

tion, it shall be MOTOR Rotation Malfunction

(REEL Malfunction).

2) DRUM Malfunction detection

Detect the DRUM rotation at the D-FG input termi-

nal.

If the variation of D-FG input level is not detected

for a lapse of 1 sec. or more when D-CONT is "H",

it shall be assumed to be Rotation Malfunction and

be DRUM Malfunction.

When detect Drum Malfunction, POWER shall be

turned OFF after the unit switches over to STOP

(B) Mode.

3) Countermeasure for TAPE LOADING Malfunction

Detect the Malfunction with the LOADING Switch.

a) TAPE LOADING Malfunction

If LD-SW does not go to the established position

after a lapse of 7 sec. or more from TAPE LOAD-

ING or TAPE UNLOADING start, the LOADING

function shall immediately be stopped and POWER

be turned OFF, and inform the Timer about the

LOADING Mechanical Malfunction.

b) LD-SW Position Malfunction at each mode

When the unit operates at each mode, even if the

LD-SW position changes from the established one

in its mode, it keeps the function according to its

mode.

4) Countermeasure for CASSETTE LOADING Mal-

function

a) CASSETTE IN operating Malfunction

If LD-SW does not go to SB position after a lapse

of 5 sec. or more from the CASSETTE insertion

start, the unit starts the CASSETTE OUT opera-

tion.

After switch over to CASSETTE OUT operation and

then a laps of 5 sec. or more from the CASSETTE

OUT operation start, if LD-SW does not go to the

EJ position or if START Sensor and END Sensor

does not turn "ON" at the EJ position, the unit

starts again to insert CASSETTE.

(However in S-INH state, the START/END Sensor

shall be disabled).

b) CASSETTE OUT operating Malfunction

After a lapse of 5 sec. or more from CASSETTE

OUT operation start, if LD-SW does not go to the

EJ position or if START Sensor and END Sensor

does not turn "ON" at the EJ position, the unit

starts to insert CASSETTE.

(However in S-INH state, the START/END Sensor

shall be disabled).

When the unit switches over to CASSETTE inser-

tion at CASSETTE IN or CASSETTE OUT Mal-

function, if LD-SW does not go to the SB position

after a lapse of 5 sec. or more from CASSETTE

insertion start, the function shall immediately be

stopped and POWER be turned OFF, and the unit

be CASSETTE LOADING Malfunction.

c) When POWER is turned ON, if the CL position or

GC position cannot be detected after 5 sec. LD-

REV operation and 5 sec. LD-FWD operation, the

function shall immediately be stopped and POWER

be turned OFF, and the unit be CASSETTE LOAD-

ING Malfunction.

d) When POWER is turned ON without CASSETTE

(EJ position) and LD-SW is monitored all the time,

if the CL or GC position is detected continuously for

1 sec. or more, the POWER shall be turned OFF

and the unit be CASSETTE LOADING Malfunction.

Countermeasure for Mechanical

Malfunction

If the unit detects Mechanical Malfunction, turn the

POWER OFF. If the unit is Mechanical Malfunction,

Key input except POWER key shall be disabled and

CASSETTE insertion disabled. When POWER Key is

entered, the POWER is turned ON and the unit

switches over the EJECT Mode. (Return with POWER

ON)

Содержание TVCR-2104

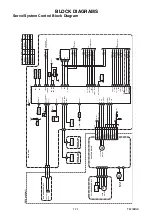

Страница 17: ...1 5 4 T6700DC Fig 4 S 11 S 11 S 11 S 11 Anode Cap 11 CRT CRT CBA...

Страница 37: ...Main 2 5 Schematic Diagram 1 8 5 1 8 6 T6700SCM2...

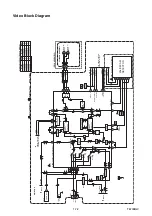

Страница 42: ...1 8 15 1 8 16 H V Power Supply 2 2 Schematic Diagram T6700SCP2...

Страница 43: ...1 8 17 1 8 18 T6700SCCRT CRT Schematic Diagram...

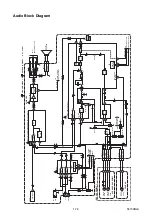

Страница 86: ...2 4 9 Z13PDA Fig DM16 43 41 42 L 13 Fig DM17 44 45 Slide P 9...