6

Problem

1. The hose does not stop

in the correct position.

2. Leakage sound in bearing.

Possible cause

Hose stop.

The negative pressure in

the system is too high.

Bearing worn out.

Actions

Adjust the position of hose stop.

Lower the negative pressure (max. 2500 Pa).

Change bearing.

6 Care Instructions

6.1 Activation

Disruptions caused by lack of or faulty

maintenance may result in high costs for the

product.

The checklist for maintenance is designed for normal use of

the product. The recommended intervals are approximate

and refer to the time after the first startup. Depending on

the changing operating conditions between the different

systems, the intervals for recommended maintenance may

differ. The user should therefore determine their own

maintenance intervals.

Please remember that only original spare parts

may be used.

When replacing damaged fasteners, only those of identical

quality (strength, material) and type may be used

.

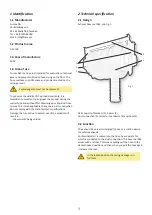

3.2.2 Hose selection

Select the appropriate hose length, see table.

If using your own hose, use accessory AES 200,

a hose stop that meets the safety requirements

for the product.

For information relating to AES see

8 Accessories

.

Max. rolled-up hose Ø200 mm is 11 metres.

4 Operating instructions

4.1 Installation and startup

4.1.1 Before startup

Before startup the device, read the instructions

provided in

chapter 2.4 Safety

.

4.1.2 Assembly and operation

Any faults must be rectified before

operational startup.

1.

Check that any electrical connections are correctly

performed.

5 Troubleshooting

5.1 Troubleshooting guide

Содержание ASE 130

Страница 1: ...MANUAL A18W35_MASE 130_F_EN...