User’s Manual for FD556 Digital 2-Phase Stepper Driver

User’s Manual for FD556 Digital 2-Phase Stepper Driver

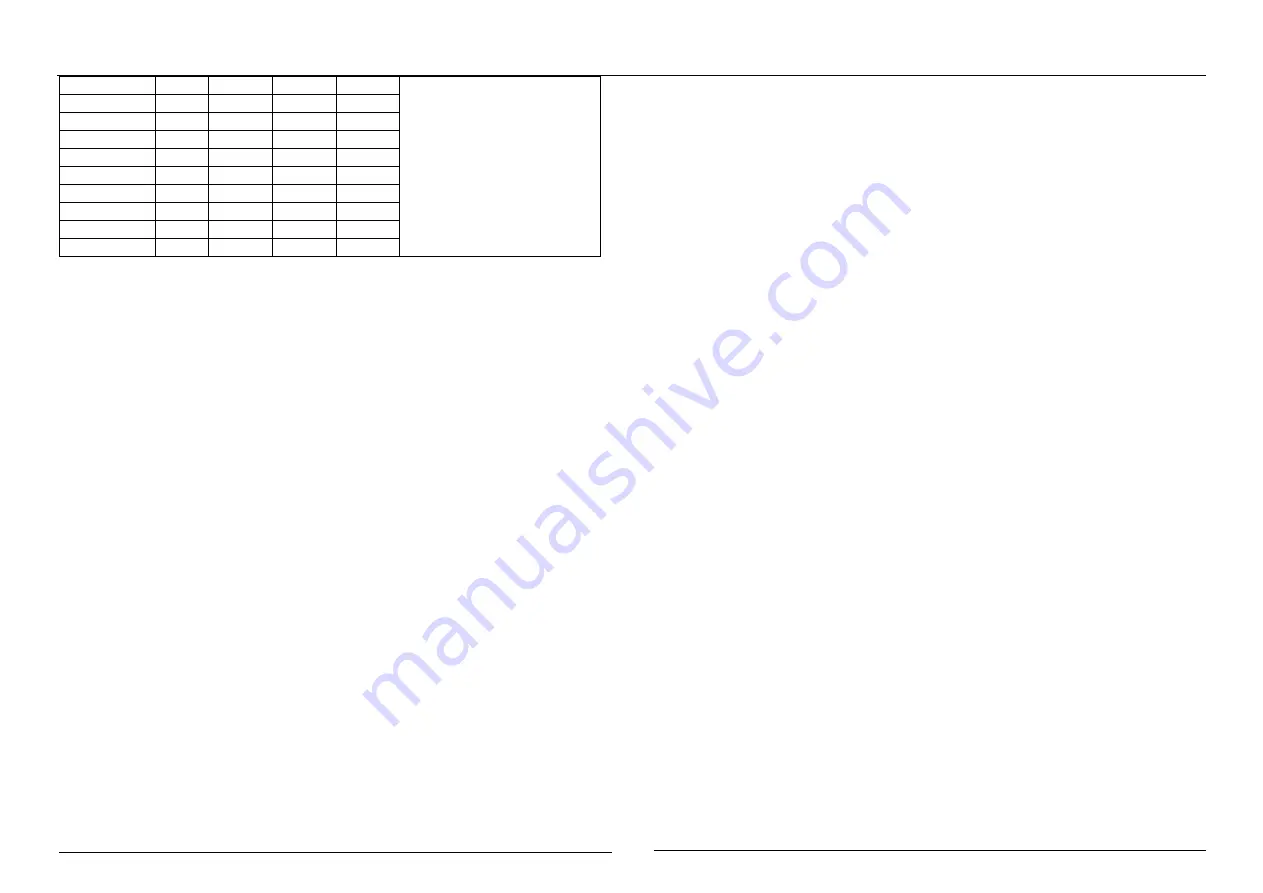

11 12

12800

on

off

off

on

ProTuner software or STU

debugger to set the number of

resolutions, the minimum value

is 1, the resolution is 1, and the

maximum value is 51200.

25600

off

off

off

on

1000

on

on

on

off

2000

off

on

on

off

4000

on

off

on

off

5000

off

off

on

off

8000

on

on

off

off

10000

off

on

off

off

20000

on

off

off

off

25000

off

off

off

off

3. Parameter auto-tuning function

If SW4 is toggled return in 1S, each parameter of the motor can be automatically

identified once at each instant of powered-on, and the driver can automatically complete

the auto-tuning of the motor parameters and internal adjustment parameters. To get the

optimized performance, please repower the driver will auto-identify the new motor and

auto-configure related control parameters when the motor power supply voltage and other

conditions change.

Note that pulse can’t be input, the direction signal should not be changed, and the

enable signal can’t be connected at this time.

Ⅴ

.Power Supply Selection

It is important to choose appropriate power supply to make the driver operate

properly and deliver optimal performance. Both unregulated and regulated power

supplies can be used to supply DC power to the FD556S driver. If regulated power

supply is indeed used, voltage ripple peak value after rectification doesn’t exceed its

specified maximum voltage. Therefore, it is suggested to use power supplies with

theoretical output voltage of no more than its defined voltage, leaving room for power

line fluctuation.

If regulated power supplies (such as most switching supplies.) are indeed used, it is

important to have large current output rating to avoid problems like current clamp.

Please Note:

1

)

Power Supply polarity not then reversed.

2

)

Best to use an unregulated power supply.

3

)

if unregulated supply is used, The power supply current output capacity should be

greater than 60% of the driver setting current.

4

)

if regulated supply is used, the average current withdrawn from power supply is more

than or equal to driver current.

5

)

It is recommended to have two or three drives to share one power supply to reduce

cost, if the supply has enough capacity.

Ⅵ

.Motor option

The FD556S can drive any 2-phase and 4-phase of 4, 6, 8-lead hybrid stepping motors,

which is suitable for 1.8°and 0.9°step angle motor. When selecting a motor, it is mainly

determined by the torque and rated current of the motor. The torque is determined by the

size of the motor, the larger the size of the motor, the larger the torque.

While the current is mainly related to the inductance, the small-inductance motor has

good high-speed performance, but larger currents.

1. Motor Option

1

)

Determine load torque, transmission ratio and working speed range.

T

电机

=C

(

Jε+T

负载

)

J

:

Moment of inertia of load

ε

:

Maximum angular acceleration of the load

C

:

Safety factor, recommend 1.2~1.4

T

负载

:

Maximum load torque, Contains resistance torque such as payload, friction,

transmission efficiency.

2

)

What factors determine the motor output torque

●

For a given stepping motor and coil connection, the output torque has the following

characteristics.

●

For a given motor, higher driver current will make the motor to output more torque,

but at the same time causes more copper loss heating in the motor and driver.

●

Higher supply voltage can increase motor torque at higher speeds, thus helpful for

avoiding losing steps.

●

From the torque-frequency characteristic diagram

of the stepper motor, the High-speed

torque is smaller than that of the medium-low speed.