User’s Manual for FD556 Digital 2-Phase Stepper Driver

User’s Manual for FD556 Digital 2-Phase Stepper Driver

9 10

4

)

t4: Low level width not less than 2us.

4. Control Signal Mode Setting

Pulse trigger edge and single/double pulse selection:

By PC software (ProTuner

software) or STU debugger set the rising or falling edge trigger of the pulse is a valid,

and set single or double pulse mode. In the double-pulse mode, the signal at the direction

control terminal must be kept high or left floating.

5. Wire Connection

1) In order to improve anti-interference performance of the driver, it is recommended to

use twisted pair shield cable, and the shield is shorted to ground, Except for special

requirements, the shielded wire of the control signal cable is also shorted to

single-ended ground. The upper end of the shielded wire is grounded, and the driver

end is floating. Only allowed on the same point grounding in the same machine, If it

is not a real ground wire, the interference may be serious, and the shielding layer is

not connected at the time.

2) To prevent noise incurred in PUL/DIR signal, pulse/direction signal wires and motor

wires should not be tied up together. It is better to separate them by at least 10 cm,

otherwise the disturbing signals generated by motor will easily disturb pulse direction

signals, causing motor position error, system instability and other failures.

3) If a power supply several drivers, parallel connection is recommend instead of

daisy-chaining.

4) It is prohibited to pull and plug power connector P2 while the driver is powered ON,

because there is high current flowing through motor coils (even when motor is at

standstill). Pulling or plugging power connector P2 with power on will cause

extremely high back-EMF voltage surge, which may damage the driver.

5) It is strictly forbidden to add lead to the terminal after adding tin, otherwise the

terminal may be damaged due to the increased contact resistance.

6)

Lug must not be exposed outside the terminal to prevent accidental short circuit and

damage to the driver.

Ⅳ

. Driver Current Output, Selecting Microstep Resolution

and Parameter auto-tuning function

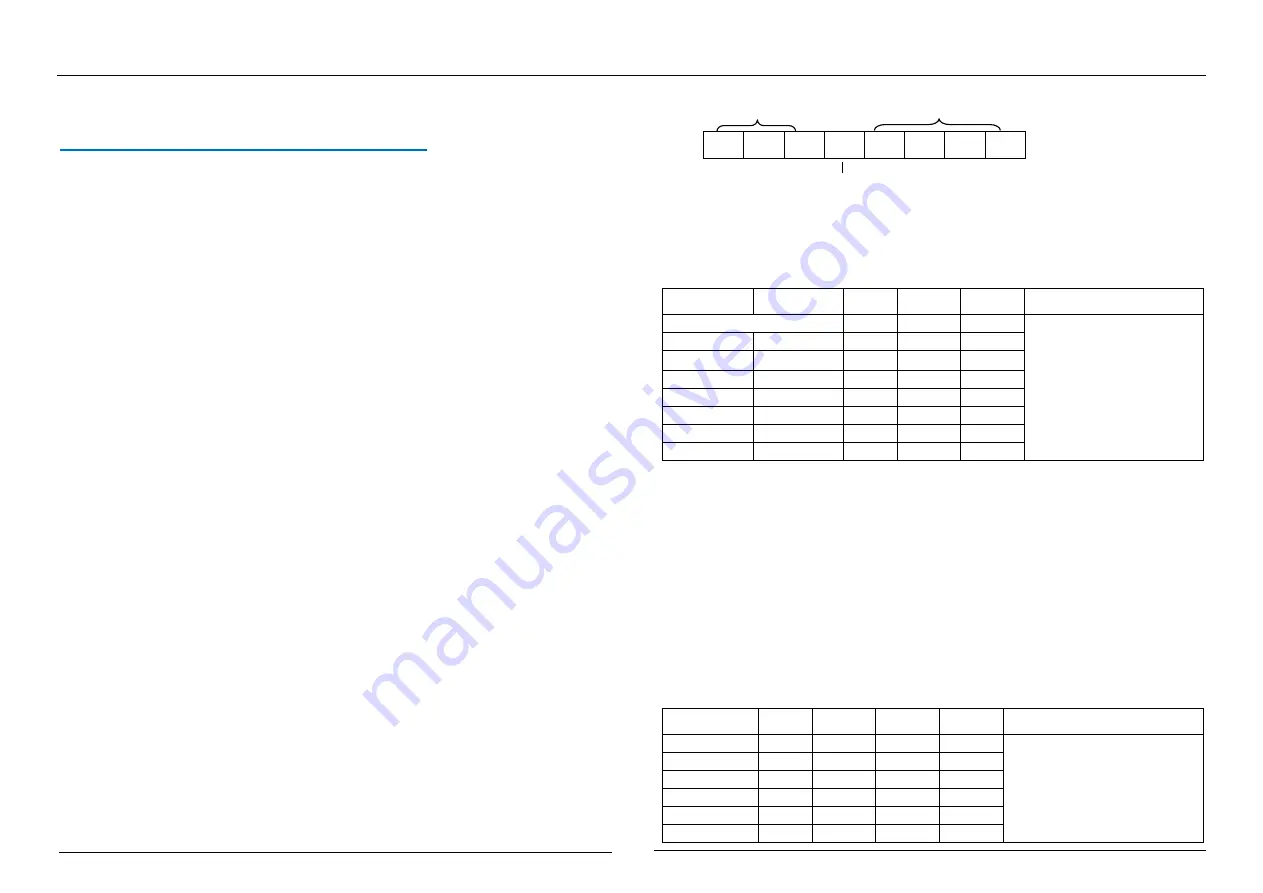

This FD556S driver uses an 8-bit DIP switch to set microstep resolution, motor

dynamic current, standstill half-current, motor parameters and internal adjustment

parameters auto-tuning, as shown below:

SW1 SW2

SW3 SW4 SW5

SW6 SW7 SW8

1 Current Setting

1

)

Dynamic current Setting

Peak Current

RMS Current SW1

SW2

SW3

Current Setting

Default[1.0A]

off

off

off

When SW1,SW2.SW3 are

set to off, it can be set to the

required current by PC

Software, Maximum value is

4.2A and resolution is 0.1A,

If it is not set, the default is

1A.

2.1A

1.5A

on

off

off

2.7A

1.9A

off

on

off

3.2A

2.3A

on

on

off

3.8A

2.7A

off

off

on

4.3A

3.1A

on

off

on

4.9A

3.5A

off

on

on

5.6A

4.0A

on

on

on

2

)

Standstill Current Setting

SW4 is used for this purpose. off means that the standstill current is set to be half of

the selected dynamic current, and on means that standstill current is set to be the same as

the selected dynamic current. In general SW4 should be set to off to enable the heat

generation of the motor and driver to be reduced and the reliability to be improved. The

current automatically reduced to 60% of dynamic current setting 400 millisecond after

the last pulse. Theoretically, This will reduce motor heating to 30% (due to P=I2*R)) of

the original value.

2. Microstep Resolution Selection

Steps/rev.

SW5

SW6

SW7

SW8

Resolution Description

Default[3600]

on

on

on

on

。

When SW5,SW6,SW7 and

SW8 are on, the driver uses the

default number of resolution

within the driver. Use PC

400

off

on

on

on

800

on

off

on

on

1600

off

off

on

on

3200

on

on

off

on

6400

off

on

off

on

Microstep Resolution Setting

Half Current/Full Current Parameter Setting

Dynamic current Setting