En-34

CAUTION

Do not reuse the refrigerant that has been recovered by the recovery pump.

To prevent the discharge of the refrigerant into the atmosphere, follow the procedure indicated below to recover the refrigerant from an

outdoor unit before moving or discarding the unit. Up to approximately 20 kg can be recovered per outdoor unit. If the volume of the

refrigerant to be recovered is large, recover it into a refrigerant recovery cylinder while measuring the weight of the refrigerant.

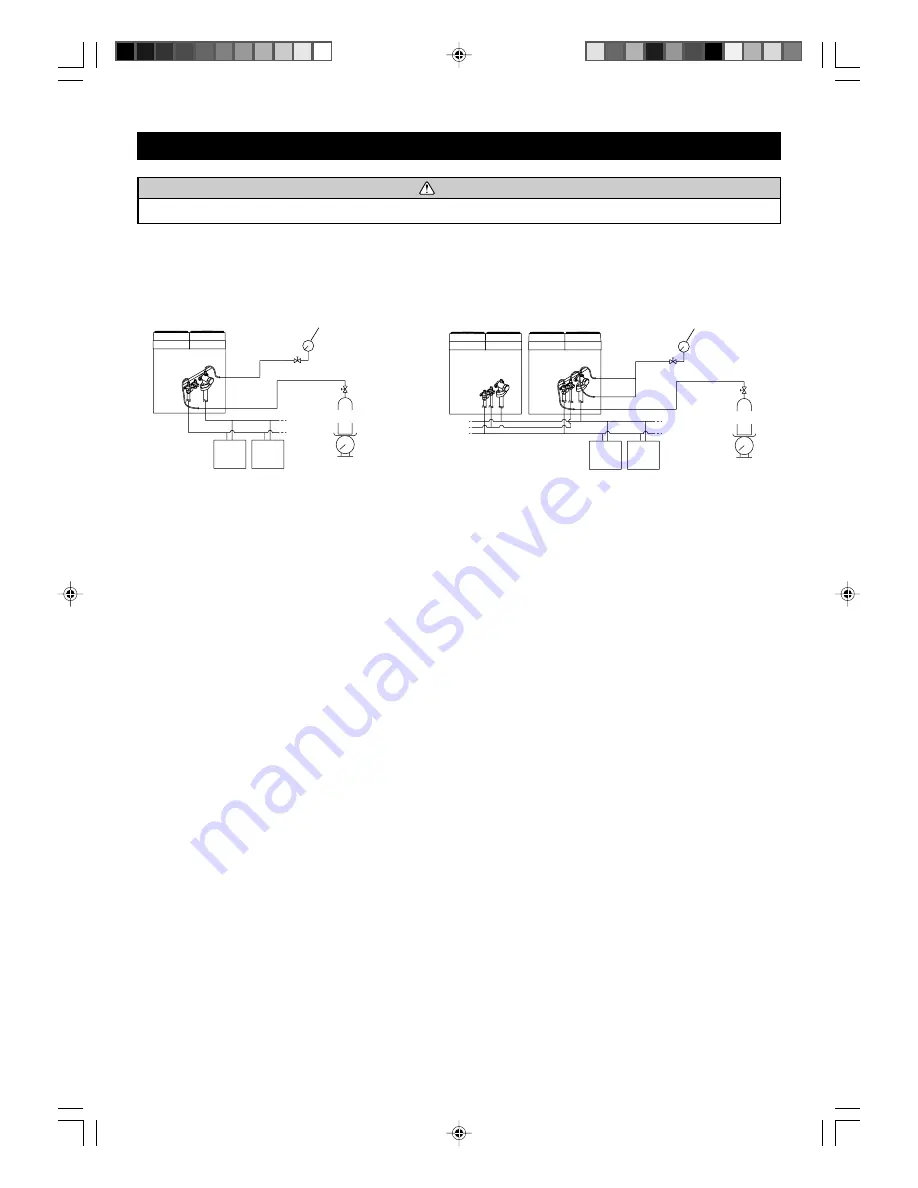

Fig. 8-1 Connecting system

A) In case of connected outdoor unit

B) In case of connected many outdoor units

Single unit Installation

Pump down method 1 (DIP switch method)

1. Fully close the 3-way valve at the liquid pipe.

2. Set the DIP switch 1-3 on the outdoor unit board “OFF

→

ON”.

The unit will start automatically in the cooling mode.

3. When the pump down is completed, the LED lamps will flash

at LED 2 to 6.

4. After the LED lamps flash, fully close the 3-way valve at the

gas pipe within 2 minutes, otherwise the compressor may be

damaged.

5. Restore the DIP switch to the original setup. (ON

→

OFF)

Pump down method 2 (manual method)

1. Connect the charge hose of the manifold gauge to the charge

port of the 3-way valve at the gas pipe. Open the pressure

reduction valve slightly to purge the air from the charge hose.

2. Fully close the 3-way valve at the liquid pipe.

3. Perform a test run in the cooling mode.

* Set the DIP switch SW1-1 to “OFF

→

ON”.

4. When the pressure gauge reads between 0.05 and 0 MPa,

fully close the 3-way valve at the gas pipe and stop the run

promptly.

Set the DIP switch SW1-1 to “ON

→

OFF”.

If the unit continues to run with the pressure at 0 MPa, the

compressor may be damaged.

In case there is too much refrigerant

1. Connect a gas cylinder to the charge port at the liquid pipe.

2. Perform a test run in the cooling mode.

* Set the DIP switch SW1-1 to “OFF

→

ON”.

* If the refrigerant is difficult to recover, fully close the 3-way

valve at the liquid pipe.

3. After recovering the refrigerant using the gas cylinder, stop

the run.

Set the DIP switch SW1-1 to “ON

→

OFF”.

4. Perform the pump down operation according to the method

describe above.

Indoor

unit

Outdoor unit

Indoor

unit

Empty cylinder

Scale

Pressure

gauge

Outdoor unit

Outdoor unit

Empty cylinder

Scale

Pressure

gauge

Indoor

unit

Indoor

unit

Multiple connections

Pump down method 1 (DIP switch method)

1. Fully close the 3-way valves at the liquid pipes.

Fully close the 3-way valves at the oil pipes of the slave units.

* Leave only the 3-way valve at the oil pipe of the master unit

fully open.

2. Set the DIP switch 1-3 on the outdoor unit board “OFF

→

ON”.

(the master unit board)

The unit will start automatically in the cooling mode.

3. When the pump down is completed, the LED lamps will flash

at LED 2 to 6.

4. After the LED lamps flash, fully close the 3-way valve at the

gas pipes and the 3-way valve at the oil pipe on the master

unit within 2 minutes.

Restore the DIP switch to the original setup. (ON

→

OFF)

If the 3-way valves are open for more than 2 minutes, the com-

pressor may be damaged.

* If it will be difficult to close the 3-way valves for all units

during the 2 minutes while the LED lamps are flashing, close

the valves a little before performing the pump down opera-

tion.

Pump down method 2 (manual method)

1. Connect the charge hose of the manifold gauge to the charge

port of the 3-way valve at the gas pipe. Open the pressure

reduction valve slightly to purge the air from the charge hose.

2. Fully close the 3-way valves at the liquid pipes.

Fully close the 3-way valves at the oil pipes of the slave units.

* Leave only the 3-way valve at the oil pipe of the master unit

fully open.

3. Perform a test run in the cooling mode. (the master unit board)

* Set the DIP switch SW1-1 to “OFF

→

ON”.

4. When the pressure gauge reads between 0.05 and 0 MPa,

fully close the 3-way valves at the gas pipes and the 3-way

valves at the oil pipes on all units and stop the run promptly.

Set the DIP switch SW1-1 to “ON

→

OFF”.

If the unit continues to run with the pressure at 0 MPa, the

compressor may be damaged.

In case there is too much refrigerant

1. Connect a gas cylinder to the charge port at the liquid pipe.

2. Perform a test run in the cooling mode. (the master unit board)

* Set the DIP switch SW1-1 to “OFF

→

ON”.

* If the refrigerant is difficult to recover, fully close the 3-way

valve at the liquid pipe.

3. After recovering the refrigerant using the gas cylinder, stop

the run.

Set the DIP switch SW1-1 to “ON

→

OFF”.

4. Perform the pump down operation according to the method

describe above.

8. PUMP DOWN

9374241033_IM_en_p18-36.p65

26/8/2008, 18:24

34