14

920-087-04

Section III – Chassis Installation

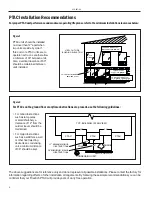

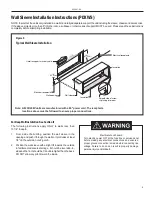

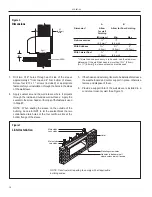

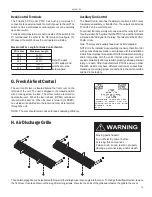

1. Remove the weatherboard and center support from the sleeve

(if still in place). Be sure an outdoor grille is attached.

Check to be sure the wall sleeve, extension (if used), grille, and drain kit are installed properly before chassis installation.

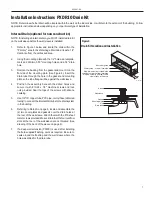

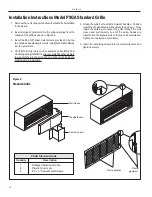

2. Remove the front cover contained in a protective plastic bag

from chassis. Remove the bag and dispose of it properly.

If the control door is not installed, follow these steps:

• From the front of the cover, slide the right control door pin

into the hole on the right side of the front cover. Slide the

left door pin into the hole on the left side of the front cover

opening and snap it into place.

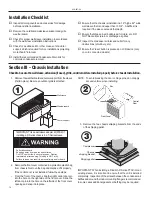

3. Remove the two chassis shipping brackets from the ends

of the shipping pallet.

NOTE: To avoid breaking the door or hinge pins, do not apply

excessive force when installing

Suffocation hazard

Keep bag away from babies and children.

Do NOT use in cribs, beds or playpens. Destroy

immediately after opening. This bag is NOT a toy.

Failure to do so can result in personal injury and/or death

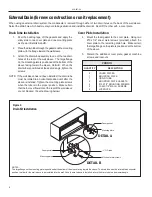

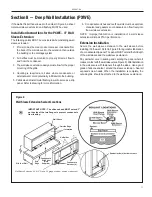

IMPORTANT: Use a wall sleeve adapter kit (PXSE) if

installing a P-Series chassis in a T-Series sleeve.

Compressor

Chassis

shipping bracket

Shipping pallet

IMPORTANT: When installing a Friedrich P-Series PTAC into an

existing sleeve, it is important to ensure that the unit is installed

completely. Inspection of the air seal between the condenser air

baffl es and around the indoor mounting fl ange is recommended.

In some cases additional gaskets or baffl ing may be required.

Wall sleeve

Weatherboard

Center support

1

Control

Door

Pins

Front Panel

2

3

Installation Checklist

Inspect all components and accessories for damage

before and after installation.

Remove the cardboard wall sleeve support and grille

weatherboard.

Check for proper wall sleeve installation in accordance

with the wall sleeve installation instructions.

Check for a subbase kit or other means of structural

support which is re quired for ALL installations projecting

more than 8" into room.

Install the recommended Condensate Drain Kits for

complete con den sate removal.

Ensure that the chassis is installed in a 16" high x 42" wide

wall sleeve that is no deeper than 13 3/4". A baffl e kit is

required if the sleeve exceeds that depth.

Ensure that drapes, bed, bedspread, furniture, etc. DO

NOT block either return or discharge air grilles.

Inspect the condenser air inlet and outlet for any

obstructions (shrubbery, etc.)

Ensure that 'reset' button is pressed on LCD device (only

on cord connected models)