140.010-IOM (APR 2018)

Page 16

IDSC/ECOSS

™

EVAPORATIVE CONDENSERS

MAINTENANCE

ü

Heavier moisture or greasy dirt must be removed with a

high-pressure water jet (max. 725 psi pressure), steam

pressure jet (max. 725 psig pressure), minimum 8 inches

away with a flat jet nozzle, or using a neutral cleaning

agent where applicable.

NOTE:

o With oily and greasy dirt it helps to add a cleaning

agent to the water.

o Cleaning should be done from inside to the outside

(always opposing the dirt onset) and from top to bot-

tom.

o Continue cleaning until all dirt has been removed.

WATER TREATMENT

WATER TREATMENT AND MINIMUM WATER

QUALITY REQUIREMENTS

Biological Control

With the inlet louvers structure of the side coverings, which

effectively shut out the sunlight and the double inclination

of the basin for complete drainage, it is ensured that there

will be minimal biological growth in the basin.

Chemical treatment

For necessary measures to maintain the prescribed limit

values (see Table "Recirculated Water Quality Guidelines),

please contact your local water treatment specialist.

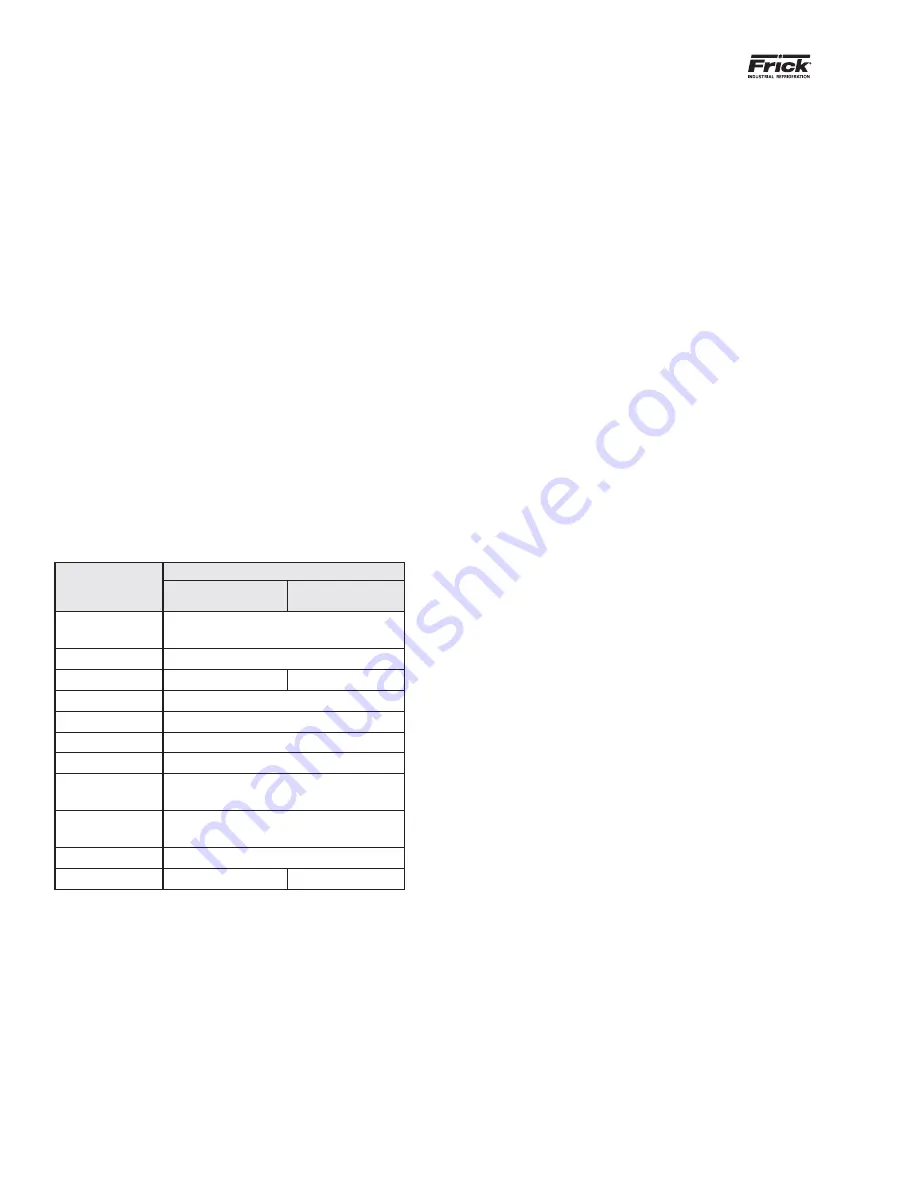

Recirculated Water Quality Guidelines

Property

Recommended Value

304L SST

316L SST

(Std. Tube Material)

Total Bacteria

(cfu/ml)

< 1,000

pH (90

°

F)

6.0 - 9.0

Chlorides as Cl

< 250 ppm

< 400 ppm

Sulfates as SO

4

2-

< 250 ppm

Silica

< 150 ppm

Hardness

< 500 ppm (as CaCO

3

)

Alkalinity

< 600 ppm (as CaCO

3

)

Total Dissolved

Solids

< 1,500 ppm

Total Suspended

Solids

< 40 ppm

Conductivity

< 3,000 (micromhos)

Free Chlorine

< 1.0 ppm

< 2.0 ppm

NOTES:

1. The water quality guidelines listed above are for clean

surfaces. Proper and periodic equipment maintenance is

required to prevent tube fouling, surface deposit(s), scale,

microbial deposit(s), etc. which in turn can reduce the range

of the guidelines provided above.

2. Water distribution nozzles are to be kept clean at all times

to ensure complete wetting of the coil. Failure to do so will

result in warranty being voided.

3. Only Non-Chlorinated Biocides should be used for biologi-

cal control.

4. Anaerobic dip slide: Sessile bacteria sampling must be

conducted along with bulk water (planktonic) sampling.

Water Treatment Guidelines:

Water related problems that typically occur in an evaporative

condenser can be broadly classified as:

•

Scale Deposits

• Corrosion

•

Microbiological Fouling

Scale deposits are a serious concern in evaporative heat

transfer products. When dissolved solids become overly

concentrated, an adherent deposit termed "scale" will form

on the tubes of the heat exchanger, severely impacting the

thermal performance of the heat exchanger. Evaporative

cooled deposits may also include dust scrubbed from the

air, corrosion byproducts and microbiological contaminants

(slime). Regardless of the source, the end result is reduced

thermal performance, increased operating costs and eventu-

ally, equipment failure.

Corrosion in water is usually an electrochemical reaction

initiated by the presence of naturally occurring impurities in

water or microbiological growth. Corrosion is the destructive

reaction of a metal with its immediate environment, resulting

in metal loss and ultimately equipment failure.

Metal corrosion occurs as a result of galvanic action at a

negatively charged pole, or site on the metal surface. Both

anodes and cathodes can be created on metal surfaces due

to impurities in the metal, localized stress, metal grain size

or composition differences. The difference in charges be-

tween anodes and cathodes creates an electrical potential

between them which results in an electrical charge flowing

from anodes to cathodes, using the surrounding water was

a conductor. General corrosion is wide spread and normally

caused by impurities in the metal or characteristics of the

metal or its environment that results in an overall fouling of

the metal surface. Localized corrosion results from stress or

localized environment.

Having a consistent maintenance program in place and

maintaining the equipment in a clean state all ascribe to the

longevity of IDSC/ECOSS units.

Microbiological fouling results from bacteria, fungi, zooplank-

ton and algae introduced into the system through makeup

water or filtered from the air. Fouling results when these

microorganisms grow in open systems rich in oxygen and

form slime on the surfaces of the equipment. Slime is an

aggregate of both biological and non-biological materials.

The best method of controlling biological fouling in evapora-

tive units is to keep them clean. At least twice during the

cooling season, the unit should be drained, scrubbed clean

and allowed to dry fully before refilling. Thereafter, a chemical

treatment will complete the process.

Uncontrolled microbiological fouling can cause major corro-

sion and deposit problems in evaporative units. Microbials in

condenser water systems can become resistant to a single

method of treatment, therefore it is recommended that both