Содержание MCC-120 H

Страница 25: ...Rev 5 Service Manual MCC Hot USA 20220500 Page 25 5 1 MCC 90 Drop in Dimensions Self Serve For reference...

Страница 27: ...Rev 5 Service Manual MCC Hot USA 20220500 Page 27 5 3 MCC Hot Drop in Specifications Self Serve For reference...

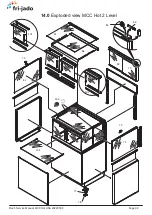

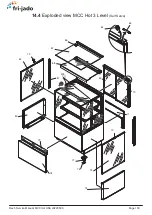

Страница 35: ...Rev 5 Service Manual MCC Hot USA 20220500 Page 35 6 0 Installation Front door section first version...

Страница 52: ...Page 52 Rev 5 Service Manual MCC Hot USA 20220500 Page 2 Instruction Controller replacement...

Страница 80: ...Page 80 Rev 5 Service Manual MCC Hot USA 20220500 13 0 Technical Specifications MCC Hot 2 Full Serve US...

Страница 81: ...Rev 5 Service Manual MCC Hot USA 20220500 Page 81 13 1 Technical Specifications MCC Hot 2 Self Serve US...

Страница 82: ...Page 82 Rev 5 Service Manual MCC Hot USA 20220500 13 2 Technical Specifications MCC Hot 3 Full Serve US...

Страница 83: ...Rev 5 Service Manual MCC Hot USA 20220500 Page 83 13 3 Technical Specifications MCC Hot 3 Self Serve US...

Страница 85: ...Rev 5 Service Manual MCC Hot USA 20220500 Page 85 13 5 Technical Specifications MCC Hot 4 Full Serve US...

Страница 118: ...Page 118 Rev 5 Service Manual MCC Hot USA 20220500 15 2 1 Electrical schematic MCC Hot Self Serve Three phase...

Страница 119: ...Rev 5 Service Manual MCC Hot USA 20220500 Page 119 15 2 2 Electrical wiring MCC Hot Self Serve Three phase...

Страница 121: ...Rev 5 Service Manual MCC Hot USA 20220500 Page 121 Page intentionally left blanc...

Страница 122: ...Page 122 Rev 5 Service Manual MCC Hot USA 20220500 15 3 Circuit Diagram MCC Hot Full Serve first version...

Страница 124: ...Page 124 Rev 5 Service Manual MCC Hot USA 20220500 15 5 Circuit Diagram MCC Hot Full Serve second version...