NT 1963 E – 07/2020 _______________________________________________________________ 41

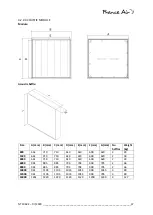

3.3.2.

ELECTRIC THERMAL MODULE

Size

Power (kW)

I

max

per phase (A)

Power supply (V)

800

22.5

32.6

3-PH., 400 – 50 Hz

1500

22.5

32.6

3-PH., 400 – 50 Hz

4000

22.5

32.6

3-PH., 400 – 50 Hz

6000

48

69.6

3-PH., 400 – 50 Hz

8000

48

69.6

3-PH., 400 – 50 Hz

10000

72

104.3

3-PH., 400 – 50 Hz

12000

72

104.3

3-PH., 400 – 50 Hz

16000

90

130.4

3-PH., 400 – 50 Hz

4.

INSTALLATION

4.1.

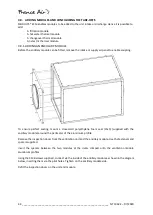

HANDLING AND MOUNTING THE PRODUCT

The unit must be installed so as to enable access for maintenance, service or removal operations. This

mainly means access to the removable panels, the electrical connections and to the panel equipped

with the fan unit.

4.2.

POSITIONING

The MODULYS® ECM module can be installed in every position, unless used with one or more ancillary

modules. In this case, the MODULYS® ECM module must be positioned horizontally.

WARNING

Under no circumstances must the maintenance panel be obstructed:

-

To enable the maintenance operations

-

To enable free access for setting the controller

-

To enable the fan motor assembly to cool down in case of fire

4.3.

AIR FLOW CONNECTIONS

Connect the MODULYS® ECM take-off directly onto the circular duct.

The connected ducts must have the same dimensions as the inlet and supply air take-off. A unit power

drop can be observed if ducts of smaller diameter are used, as well as in certain cases a reduction in

fan service life.

Connect the inlet and air supply take-offs (circular take-off) via flexible connectors (sleeves), to prevent

transmission of vibrations.

All ventilation duct connectors on the unit must be sealed with mastic or sealing tape.

The minimum distance between bends in the air ducts or adapters and the unit take-off is 3 times the

take-off diameter.

4.4.

RECTANGULAR DAMPER CONNECTIONS

The fresh air inlet will be closed when the machine is switched off. The damper installation

procedure is as follows:

•

Remove the panel with a Phillips screwdriver

•

Then unscrew the take-off throat via the inside

•

Refit the panel without the take-off throat

•

Fit the damper via 4 self-tapping screws