22

WWW.FORNEYIND.COM

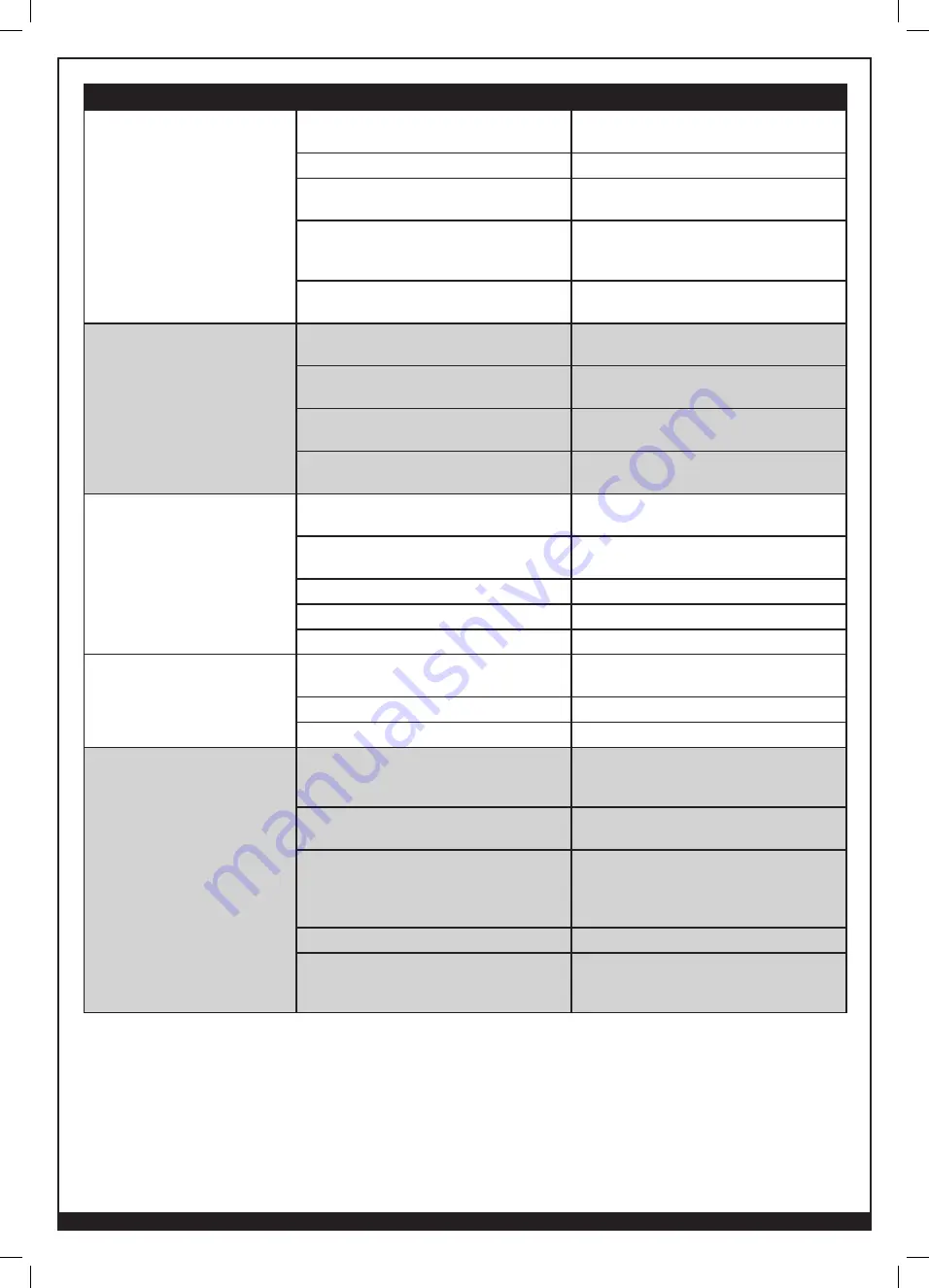

PROBLEM

POSSIBLE CAUSE

POSSIBLE SOLUTION

Birdsnesting.

Wire is not aligned with torch neck inlet guide. Ensure that the welding wire is aligned to flow

smoothly onto the torch neck inlet guide.

Wire feed too low.

Increase wire feed speed.

Tension too low / too high.

Use as little tension as necessary for smooth

operation.

Welding wire is fused to contact tip.

Attempt to pull wire out of front of contact tip

with pliers. If necessary, remove contact tip

and cut welding wire. Discard contact tip.

Contact tip is too small for wire diameter.

Always use a contact tip that is one size

larger than the welding wire.

No gas flow.

Machine is in wrong process (SMAW or

GTAW).

Ensure machine is set to MIG mode (manual

2T, manual 4T, synergic 2T, synergic 4T).

Gas cylinder is closed.

Ensure that gas cylinder is fully opened. Set

flowmeter to 25-30CFH.

Gas cylinder is empty.

Ensure that the gas cylinder is not empty. If

necessary, replace gas cylinder.

Blockage in tank valve.

Remove regulator from tank. Purge tank to

clear blockage.

Soot covered / discolored welds.

Wrong shielding gas.

Always use 100% pure argon shielding gas

when welding aluminum.

“Pulling” arc instead of “pushing” arc.

When welding aluminum, push the nozzle in

the direction of the weld rather than pulling.

Gas connection loose; sucking in atmosphere.

Ensure all gas fittings are tight.

Gas flow too low.

Increase gas flow.

Gas flow too high.

Decrease gas flow.

Welding wire fused to contact tip.

Using contact tip that is the same size as

welding wire.

Always use a contact tip that is one size larger

that the welding wire.

Burn Back Time (BBT) set too high.

Turn burn back time (BBT) down.

Wire feed speed too low.

Increase wire feed speed.

Excessive spatter.

Material surface preparation needed.

Always weld on clean bright metal. Aluminum

builds up an oxide layer that is non-conductive

and extremely difficult to melt.

Wrong shielding gas.

Always use 100% pure Argon shielding gas

when welding aluminum.

Not enough shielding gas.

Ensure that gas cylinder is fully open. Set

flow meter to 25-30CFH. Ensure that the gas

cylinder is not empty. If necessary, replace gas

cylinder.

Wire feed too fast.

Decrease wire feed speed.

Stick out too long.

Shorten the distance between the gas nozzle

and the material being welded. Maintain a

distance of 3/8” to 5/8”.