3

1.1

How it works

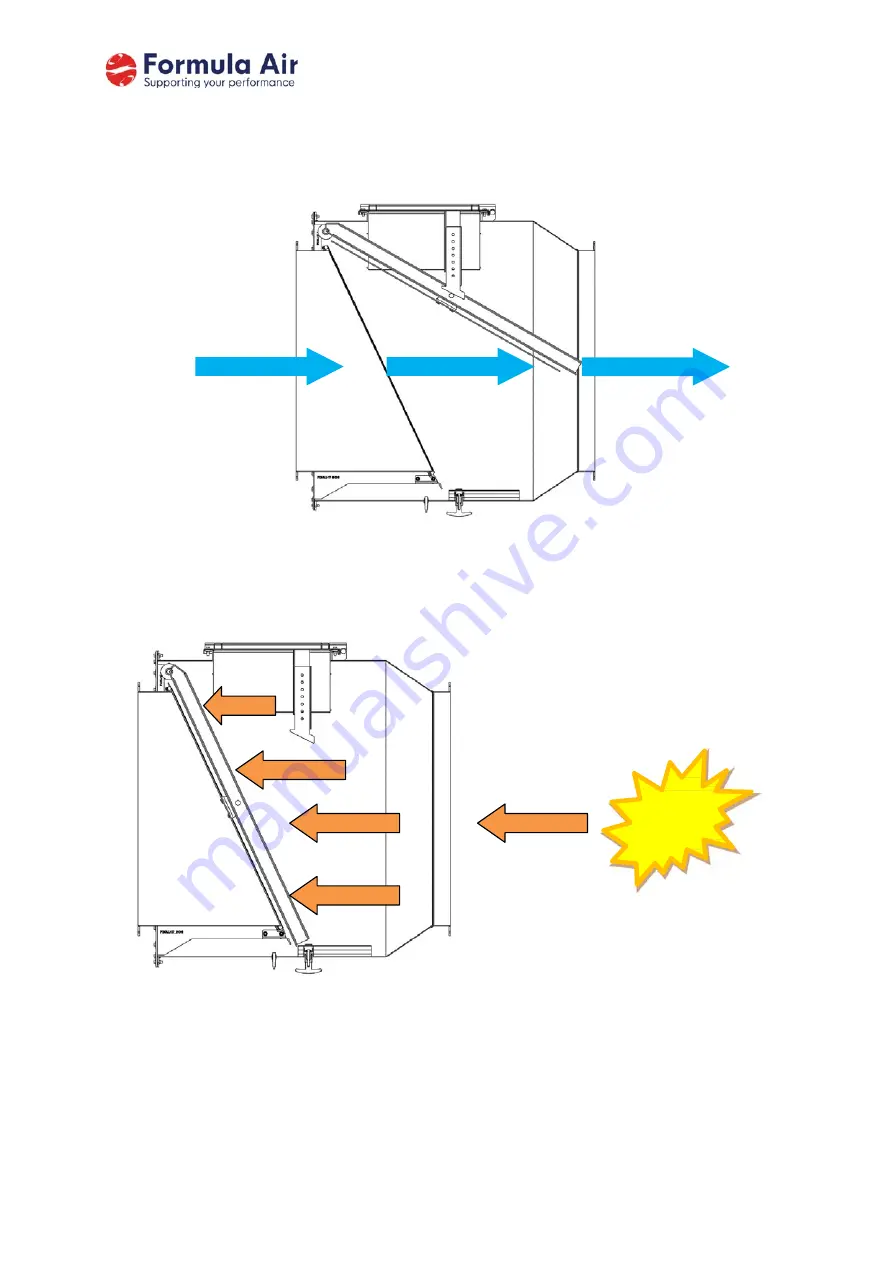

During the normal process, the non‐return valve’s flap remains opened due to the airflow

(Figure: 2). At deadlock, the valve closes due to the flap’s own weight.

Figure: 2 Non‐Return Valve in open airflow configuration

When an explosion takes place, the ATEX certified non‐return valve blocks the expansion of the

explosion due to the front spreading pressure along the ductwork (Figure: 3).

Figure: 3 Non‐Return Valve in closed configuration

After an explosion and due to pressure oscillations, the valve could re‐open. To avoid the re‐

opening, a safety lock system keeps the valve closed long enough to avoid the propagation of

flames during the explosion event, as can be seen in Figure: 4. The locking system consists of a

spring metal that allows it to bend easily. Therefore, if the flap closes the arm hits the locking

system and the top of the locking system will give in. This way, the flap gets locked beneath the

top plate of the locking system. Once the explosion is completely over, the lock must be