Installation

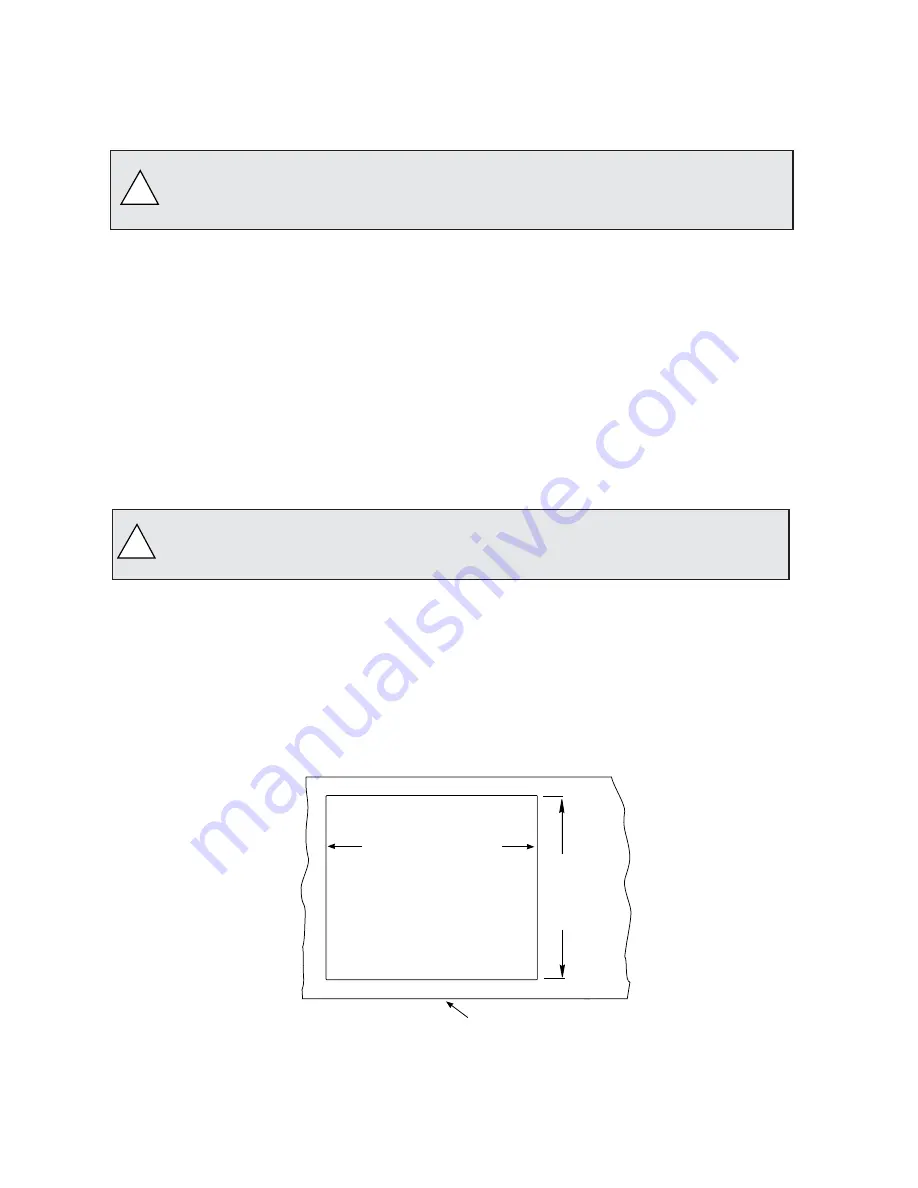

Installing MU155N dispenser in counter

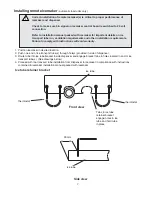

1. Check that dispenser location meets all requirements in this manual and cut counter as shown.

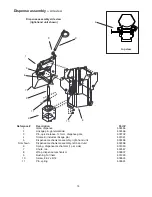

2. Block up area below counter cut-out to support dispenser when lowered into place.

3. For automatic load dispensers, disconnect ice transport tube from bracket in storage area of dispenser.

(Since this tube must be reinstalled in bracket after dispenser is dropped into counter, note how tube is held

by bracket tabs before disconnecting.)

4. Carefully lower dispenser into counter until it rests on support blocks.

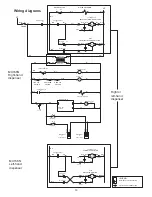

5. Adjust height from below with standard leg kit until dispenser flange rests flush with counter.

6. Apply a bead of NSF listed silicone sealant (Dow Corning RTV-732 or equivalent) approximately 6mm in

diameter around perimeter of dispenser where it meets counter and smooth sealant to a 4mm radius.

7. Install a hard drain line, maintaining at least a 6mm per 304mm run slope, and insulate line to prevent

condensation.

8. Make electrical connections in accordance with applicable wiring diagrams provided, as well as NEC and

local codes. Provide disconnects within 3m of dispenser and icemaker for servicing.

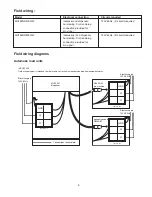

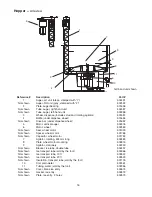

Front of counter

(772mm)

+3mm

- 3mm

(667mm)

+3mm

- 3mm

Counter cut-out

All MU155N dispensers must be installed level in both directions and supported from

below with 153 – 229mm adjustable legs provided, or channels installed on site. DO

NOT hang dispenser on flange of counter.

!

PVC pipe is suggested. Care must be taken in sweating any metal drain pipe used.

Excessive heat applied while sweating metal pipe may melt plastic fitting on

dispenser.

!

6

Содержание MU155N Series

Страница 2: ......