DRESSING THE GRINDING WHEEL

1. Shape the wheel "freehand" by holding the dresser

against the wheel while it is running. Use a circular

motion to produce the desired curvature on the

wheel.

2. Stop the motor and check the wheel shape with the

radius gauge.

3. The chart on page 7 shows the recommended

wheel thickness for different chains.

A narrower wheel may be used instead of the one

recommended in the chart, if it is dressed as shown

in Fig. No. 3. For example, if the chart calls for a

1/4

"

thick wheel, a 3/16" thick wheel can be dressed

to fit one side of the 1/4

"

gauge. This will be helpful

on certain chains where the thicker wheel may in-

terfere with the depth gauges.

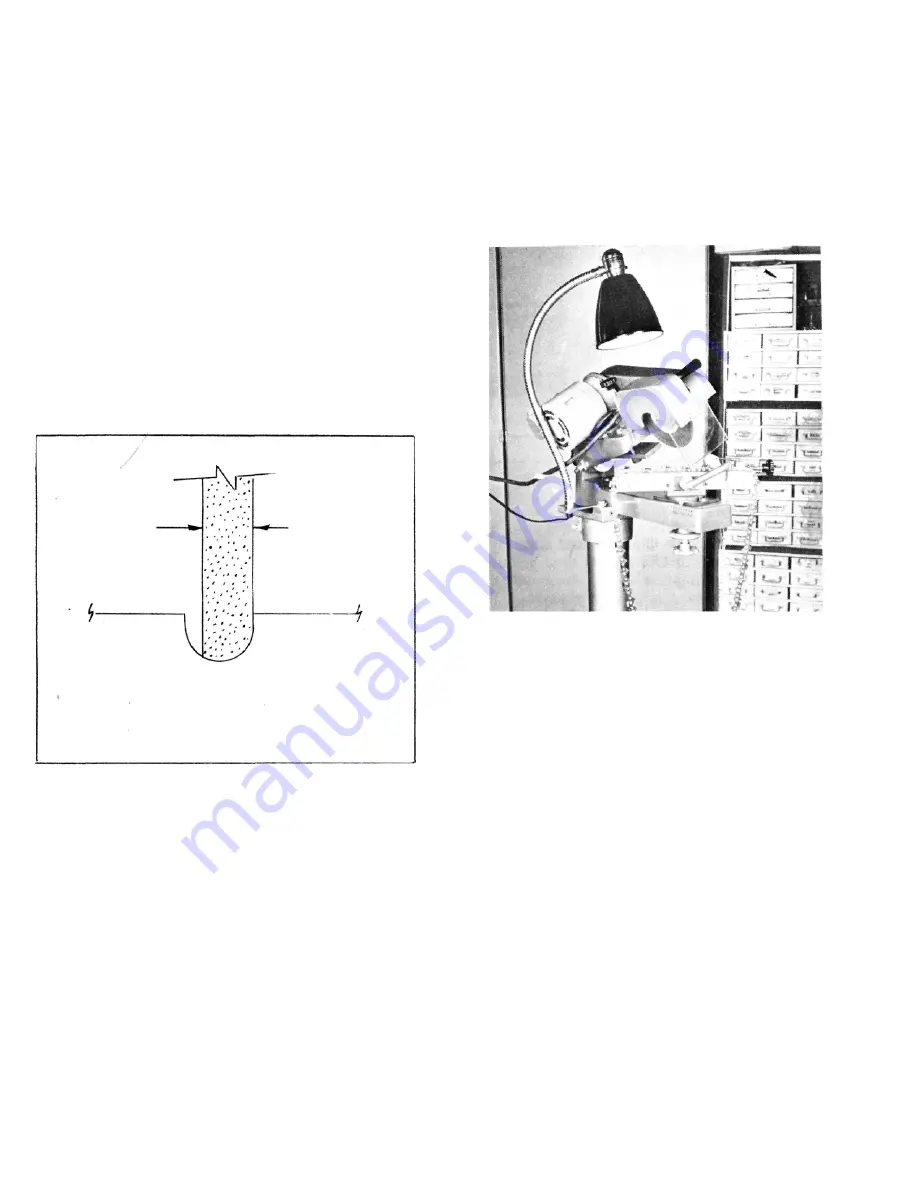

Illustration No. 3

GRINDING CHIPPER CHAIN

1. Choose and dress the grinding wheel as explained

above. Refer to Fig. No. 6 for correctly ground chip-

per cutter.

2. Lay the chain in the vise with the cutting edges fac-

ing to the left.

3. Tilt the grinding head to 30° and lock.

4. Set and lock the chain vise at 35° to the left (rotat-

ing clockwise from 0°). See Illustration No. 4.

5. Set chain vise to 0° on the horizontal scale and lock

in place.

6. Position the stop finger behind the right hand cutter

to be ground and align the tooth to the grinding

wheel. Set the depth stop.

7. Turn motor switch to "Forward" position (counter-

clockwise rotation when viewed from wheel end of

shaft) and adjust the stop finger to give the lightest

grinding pass that will sharpen the tooth properly.

Grind all right hand cutters in the chain without

changing your set up.

Illustration No. 4

Page 4

8. Swing chain vise to the right and lock at 35°. See

Illustration No. 5.

9. Position stop finger behind a left hand cutter and

align the tooth to the grinding wheel. Change only

stop finger position if necessary.

10. Grind all left hand cutters with the motor switch in

the "Reverse" position.

11. After sharpening the chain and before removing

it from the grinder check the depth gauge by lay-

ing a short straight edge across the top of two

cutters then using a feeler gauge to measure the

distance between top of depth gauge and bottom

of straight edge. Proper depth gauge setting is

shown on chart page 7... Depth gauges can also

be checked by using #370362 Oregon Adjustable

Depth Gauge.

If depth gauges need to be lowered, use a 5/16" thick

grinding wheel. Dress the wheel to match the contour

of the depth gauges (See Illustration No. 7). Set the

grinding head to 0° and to 0° on both the chain vise

scale and the horizontal scale. Set the depth control to

give proper height and grind all depth gauges.

3/16 WHEEL

1/4 GAUGE

Содержание 308

Страница 3: ......

Страница 4: ......

Страница 13: ......

Страница 15: ...394930 PEDESTAL ...

Страница 17: ......