ENGLISH

1

0

7

6

5

2

1

6

Product overview

The Vectra-Jet™ 7505 fogger atomizes light liquids into a fog, mist

or spray of small droplets. It can atomize both oil- and water-based solu-

tions, as well as emulsions and dilute suspensions of wettable powders.

Typical uses of this machine include:

• Cleaning, sanitizing and disinfecting (applying germicides or

sanitizing chemicals)

• Control of mold and mildew (applying sporicides, fungicides or

anti-mildew chemicals).

• Odor control (fogging odor neutralizers, scents or masking

chemicals)

• Humidification (fogging water).

The liquid flow rate determines the size of the fog droplets

produced. Several factors influence liquid flow rate: the setting of the flow

control valve; liquid density; liquid viscosity; and the frictional resistance

of the machine’s internal lines.

Viscosity and surface tension also affect fog droplet size. At a given

flow, lighter liquids (with lower viscosity, or lower surface tension) make

smaller droplets and finer fogs than heavier ones.

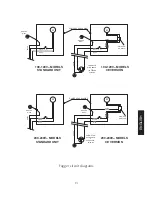

The drawing below identifies the principal components of the

machine.

FLOW CONTROL VALVE

AIR INTAKE

FILTER

COVER PLATE

LIQUID

RESERVOIR

FOG DISCHARGE NOZZLE

CARRYING

HANDLE

POWER HEAD