CAUTION:

Take care that all sensors used as references or being cali-

brated in the furnace are capable of withstanding the desired temperature

range to be used.

WARNING:

Take extreme care in handling hot probes. The ex-

treme temperatures generated in a furnace of this type can cause serious

personal injury. Do not touch them on external surfaces of the furnace or

set them on any other surfaces unable to withstand those temperatures. A

fire hazard exists. Do not touch the access tube end plate or severe burns

can result.

Some kind of metal and/or ceramic fiber surface or container should be used to

set the hot probes on to prevent injury, damage, and fire.

For best results, all reference or sample probes should be inserted into the full

depth of the well. At this position the stability is the highest and the gradient

the lowest. Each user should satisfy themselves as to what the uncertainties are

in terms of stability and gradients between the test wells. Variations in equip-

ment, probe size, configuration, etc affect these important factors. A solid

(unstirred) mass such as in a furnace is subject to heat losses from the probe

stem which varies from probe to probe and temperature to temperature. Typi-

cally, stabilities are less than ±0.1°C and can be as little as ±0.015°C at 500°C.

Similarly, gradients between the measuring cells can range from ±0.2°C to well

under ±0.1°C. For calibrations that must be less than full insertion into the test

well, make your own comparisons between the reference and test cell at that

depth to establish the uncertainties.

The furnace can be used throughout the temperature range of 300 to 1100°C.

Lower temperatures are sluggish however. High integrating values are required

to maintain controller stability (1200 sec) at the lower temperatures. Expect

some offset from the indicated temperature and the actual temperature. Stability

and gradients between test wells are similar at higher temperatures but time to

stability is much longer.

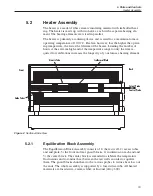

9112A Calibration Furnace

User’s Guide

24